|

|

Rank: Advanced Member

Groups: Member

Joined: 2/16/2009

Posts: 903

Location: Peace Dale, R.I.

|

I thought it might be interesting to have a discussion among the members of how they feel about using a computerized system to make models or parts, versus the tried and true method of making parts from scratch. Would you build your models entirely by computer if you had access to such a machine? Would you feel the same sense of satisfaction if all you had to do was push a button and, POOF, out comes a model? There is much to be said about Stereo Lithography and, my hat is off to anyone who learns to master the system. Since I'm an old SOB who was born before the transistor was invented, I'll have to stick with styrene and super glue. Still, it would not be so bad to sit at my computer and design a part or a model and, with a keystroke, sit and watch it come to life inside the machine.

__________________________________________________________________

Tom

It's pretty sad when the only modeling tool you own is a box cutter.

If the only tool you have is a hammer, you start to see every problem as a nail. Abraham Maslow

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/25/2006

Posts: 4,275

Location: Woodland, WA

|

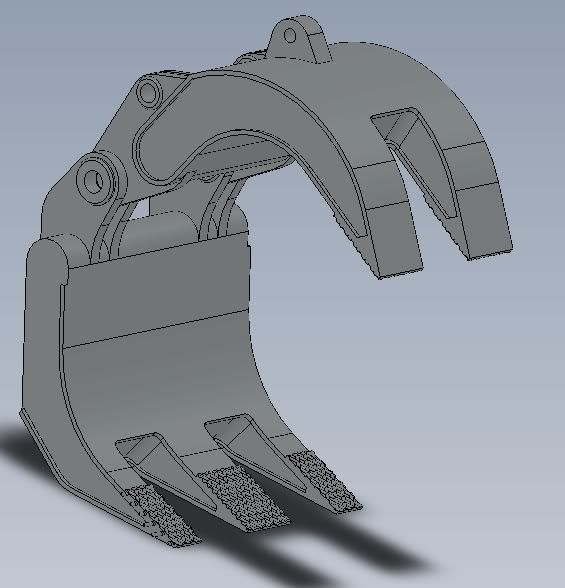

I use both processes, I bought a 3D milling machine from a fellow forum member here a few years ago, but have yet to master the process, my friend who is a full time CAD designer has been slowly showing me the ropes, For building production models, CAD design can be justified, however if you are building one-of-kind models for yourself the prototyping process can be cost prohibitive. Here is a screen shot of my most recent CAD drawing that has been underway for over a year, but will be going into production soon!

Eric W. Pioszak, Operating Engineers Local 701, Portland, OregonMETAL TRACKS AVAILABLE AGAIN! Cab guards Available again! Grapples Available again! Industrialscalemodels[at symbol]Gmail.com

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

i took a design class back in high school, and used auto cad a little bit, was pretty cool. dont really remember much about it though, was only a semester class. i like the scratch built way more. have more pride in it once its done

Brandon my youtube channelMy Facebook Page

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/13/2011

Posts: 1,021

Location: California

|

as i am new in the scratch build i think it will be good to have a computer machine but like "dude' said you just loose the the sens of building it, scratch is better for me.

SOMETHING IS BETTER THAN NOTHING. http://s1185.photobucket.com/home/vipyfz2008/indexhttp://www.youtube.com/user/vipyfz?feature=mheeluis.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/8/2006

Posts: 446

Location: Maryland

|

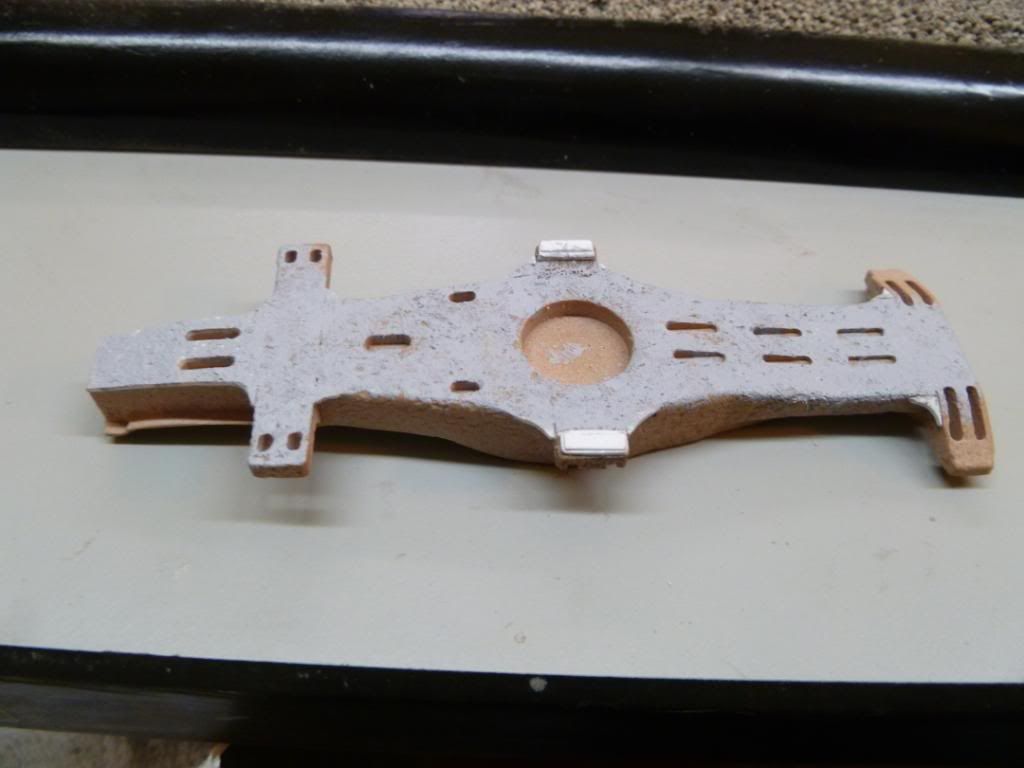

Working with brass, it is much easier to do the build in CAD than to make expensive mistakes along the way, which I have done.  An assembly design of the LR1400 that I started working on years ago. This was done in SolidWorks.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/4/2006

Posts: 7,752

Location: arlington, Tx

|

I am a hands on builder I have the razor knife and a super steady hand from doing this work for years now. But as time goes on and I have started building more complex pieces I am looking towards a laser cutting device. Doing this could speed up my build time and also save my thumb and fingers from all cuts. Now it is saving up the money to purchase a machine Jason

NIkl Scale Models

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/3/2009

Posts: 108

Location: South Yorkshire, England

|

Most of my models these days are scratchbuilt and seeing as I use CAD for my proper job, it would be great to have a CNC machine. The ease of producing the same part many times is a benefit. Just got to save up the money to buy one.

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/2/2006

Posts: 4,672

Location: New York

|

Eventually you will be able to create in CAD and print in your home in 3D any part any time with a low cost. Including metal parts generated like STL meaning you can grow a metal part we will see it soon.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/16/2006

Posts: 254

Location: spring,tx usa

|

Using Cad is only one step in scratch building. While I haven't posted any new updates on the rail car project I have been working on all summer it still is a scratch built project. Even having access to the 3D drawings of the upper half and 2D of the lower half I still have had to engineer/design it down to 1/50th scale. What CAD allows you to do is just make nice drawings though. Many people have access to different types of CAD software from rather inexpensive to full blown 3D packages. The next step is using your CAD files for CNC such as a mill, lathe, laser, 3D printing or router set up. I have spent almost as much time creating the CAM (computer aided machining) files as time I spent on CAD drawings. Granted that with the BOBCAD-CAM software I'm using is not low end and I have upgraded it quite a few times since 2005. Even with good software you have to tell it what to do. As to come up with a machine strategy of how you want to machine your part out. I have been doing only 2 1/2D machining, which is I can change the depth of the cutter for a given pass each time. 3D machining is were the depth of the cutter changes constantly to follow the part. Scratch building is a mind set. It is up to your taste and or budget as to the number and type of tools you use to create your models. After you hand tools the sky is the limit for power tools. Sure we can all dream about having parts completely printed in 3D for the whole model but that is the upper end at the moment. In another 10 years I'm sure it will be really different. In the last 5-10 years the technology for the homeshop cnc applications grown leaps and bounds. Making what once only available to professional shops affordable to the homeshop/hobbyist market. After getting your parts made by what ever means you still have to put it all together and if you haven't planned it out right it won't matter how good the parts are if they don't fit... It doesn't matter what you use to scratch build as long as you have fun doing it. There will always be some type of tool you want to move to you the next level. The next level just means more work if you can do it better and faster. Have fun with you models guys. Fritz

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/14/2006

Posts: 667

Location: The Netherlands

|

Hi Guys interesting discussion , for me one thing does not exclude the other. Making good 3D drawings does not define how to go further from there. A good 3D drawing can be a great help for a hands on builder with styrene or brass. But it can also be the step to another level , Like cnc milling , laser cutting or rapid prototyping. Cnc milling is the most difficult step ( Fritz W. explained this very well ). It cost almost as much time creating the CAM file as making the drawing. I have to say i worked at my work with Bobcad and mastercam , and now with edgecam but Bobcad is my least favorite. And mastercam was the most favorite for me , with edgecam on the second place ( but that's my personal choice ). Another thing to think about is : are you gone do it with a machine in your own hobbyshop or is it done by a third party. For cnc Milling , i think it will be difficult to have this done by a third party ( at least when you are thinking about making the cam file for them as well ). Or have them make the cam file , but that will cost you a fortune so that leaves one option left and that is having your own little cnc mill. But for laser cutting and rapid prototyping it's easy to have this done by third party's and more cost effective as well. Almost any Cad program is able to generate a decent DXF or DWG file ( for laser-cutting ) or STL file for rapid prototyping. For laser cutting do a search on google and i am sure you will find something in your area , and they can give you some info about the file format , materials and price. For rapid prototyping i have disagree a little with Fritz W saying "but that is the upper end at the moment" he is right if he means buying a machine. But you can have this done by a third party as well and it's really accessible for everyone for reasonable prices. Big advantage is that you can make complicated shapes that are impossible to make by hand. Have a good look at this site : shapeways ( especially the tutorials at the bottom of the page ). But there are more and more companies out there that are doing rapid prototyping for third party's. About the satisfaction : i have used all sorts of techniques and they all gave me the same sense of satisfaction. Bottom line , i have to quote Fritz W again "It doesn't matter what you use to scratch build as long as you have fun doing it". Eef

*** Flickr American cranes group*** 3D printed crane parts at I.materialise

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/16/2006

Posts: 254

Location: spring,tx usa

|

I know a lot of people don't really like BOBCAD. It's kinda like this, I have had it since version 19 and seen improvements along the way and I have kinda figured out how to make it work for me. Along with paying for the Service on demand for support which has been a great help when I needed it the most. I'm now using Version 24 Pro. But I also use V-Carve for nesting operations since I still like to use tabs on smaller parts and I like V-Carve over BOBCAD for nesting. In a odd way I have more program with V24 than I really need at them moment it still allows me room to grow and do more over time.

The other software from BOBCAD I use all the time is Predator CNC Editor. This allows me to run my G code and see what the tool is doing and prevent major mistakes on the mill. There is a difference between running toolpath in BOBCAD and seeing the G code with the endmill in motion against 3D stock. I have fewer problems on the mill now except for making sure I raise the endmill high enough to miss clamps on certain operations.

Mastercam is top of the line and if you can afford it or get your hands on it great. I haven't tried other CAM system than the two mentioned because you need to spend time to learn one. You can't get good software like that and expect to know how to get good results in a week or two. You have to use it to get good at it and understand how to work it. I still go back to the training videos to understand stuff I"m fuzzy on. I guess my suggestion is you need to look at support and or training to learn good software packages because there is so much to one and most operations aren't hard once you know what to do. Spru Cam is suppose to really good and is supported by Tormach PCNC but that starting over thing is not what I want to at this point in time. Maybe latter on.

Now I will admit I did mean doing rapid prototyping at home. I haven't really looked into third party and I will spend some time doing that now since complex shapes do take a lot of time to make at home on the mill. Once I have a pattern then I can cast it in resin for copies.

Great topic and glad to see it going on this site

Fritz

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/14/2006

Posts: 667

Location: The Netherlands

|

To Fritz W. The best cam software is always the one you are used to. So if you don't have an urgent reason to switch , don't. I can tell from my own experience that switching is a pain in the ***. You will remember the good functions from other software for years. So if it does the job for you keep it. Great topic indeed , take some time to look at the third party rapid prototyping. If you can do CAD and CAM this is a piece of cake. Just spit out an stl file , check it for errors and upload it or bring it somewhere on a usb stick. Looking forward to see if you are gone use it in the future , so keep us updated. Eef

*** Flickr American cranes group*** 3D printed crane parts at I.materialise

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/31/2011

Posts: 1,079

Location: Springfield, Oregon

|

I think the CAD process of building parts would be awesome for production runs of multiple parts. I don't think I'll be using any of that stuff any time soon. From the onlookers view a quality custom is always appreciated, either way, especially some of the stuff I have seen on here. I think it all comes down to what you like to do. If CAD is a challenge you're willing to take on then you should get quite a bit of satisfaction out of each part you build. I'm pretty new at this custom building thing and I'm really proud of all the things I make. They may not be to the level of quality or detail that others do but, they're just going to get beat up on my dio or dusty in my room. Still, it's a pretty cool feeling to look at something and be able to say that you built it from scratch or from pieces of multiple things. So I'll stick to the bloody fingers and Look on in awe as you guys tackle the computer aided stuff. That's my $.02

-Jason YouTubeTimberline Thinning CompanyMy Photostream

|

|

|

Guest |