|

|

Rank: Advanced Member

Groups: Member

Joined: 3/3/2014

Posts: 122

Location: Hamilton, Ontario

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/16/2006

Posts: 295

Location: Burlington, Canada

|

AWESOME!!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/3/2014

Posts: 122

Location: Hamilton, Ontario

|

Beginning the excavation for the footings   Pouring the concrete footing  Setting the base of the tower so the next layer of concrete can be poured

ZachMy Facebook PageMy YoutubeONTARIO, CANADA

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/27/2016

Posts: 93

Location: Milwaukee

|

Awesome work. Thank you

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/7/2005

Posts: 2,495

Location: Shetland

|

Very nice

Scania V8. The best sounding truck in the world.

|

|

Rank: Member

Groups: Member

Joined: 2/19/2014

Posts: 55

Location: Chesterfield Va USA

|

I love it, thank you for sharing it with us.

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/30/2008

Posts: 3,439

Location: Good ol' Indiana

|

Looks like another big project. Going to need a crane with some boom to set the blades.

-Ethan Collection 8/2/2016For more of the Diorama and my collection: On Facebook or On YouTube

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/3/2014

Posts: 122

Location: Hamilton, Ontario

|

Loading the ADT with dirt to backfill the towers   Grading out the backfilled area  The cranes are rolling in so that means our work here is done, the rest will be done by another company.  On to the next project!

ZachMy Facebook PageMy YoutubeONTARIO, CANADA

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/12/2012

Posts: 164

Location: Fayetteville, NC

|

I have searched through the forum, but I can't find that anyone has built a dio with a complete wind turbine assembly except for a small scale done by neokonig back in 2014. The pictures for this thread's 2016 dio are no longer available, but from what I remember, CanadianExcavator did an excellent pictures series focused on the foundation. Does anyone know of a source to purchase a complete wind turbine? Some of the truck hauling models have blades, nacelles, hubs, and tower sections, but they don't appear to be able to be assembled as one unit, plus the expense of buying so many trucks just for the loads is out of sight. Thanks! Ed Here is picture of what I am trying to accomplish.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

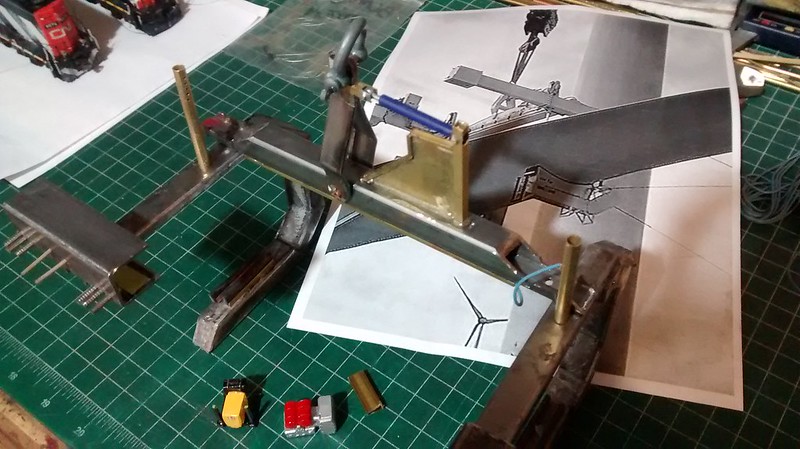

Mine is a custom project in 1:50 I did back a few years ago: 1:50 windmillAlso you may browse on this site (just click on the picture) for other related stuff:  IMG_7894 IMG_7894 by Ironstef70, sur Flickr Stef

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

Here it is: http://forums.dhsdiecast.com/default.aspx?g=posts&t=137814S

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/12/2012

Posts: 164

Location: Fayetteville, NC

|

Very impressive.

I love the lifting fixtures and I am amazed at your detail work.

I went through your Flicker pictures and your work is unbelievable. Beside the crane stuff, I really liked the billboard construction for your train layout. The weathering is so realistic!

I saw the work on motorizing the LR 1750 and wondered how you motorized the hoist drums. I am guessing you inserted a motor inside the drum, but how did you mechanically engage the drum to the motor?

did you make the turbine blades or did you purchase them? If you bought them, where did you get them from?

Thanks,

Ed.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

allisoes wrote:Very impressive.

I love the lifting fixtures and I am amazed at your detail work.

I went through your Flicker pictures and your work is unbelievable. Beside the crane stuff, I really liked the billboard construction for your train layout. The weathering is so realistic!

I saw the work on motorizing the LR 1750 and wondered how you motorized the hoist drums. I am guessing you inserted a motor inside the drum, but how did you mechanically engage the drum to the motor?

did you make the turbine blades or did you purchase them? If you bought them, where did you get them from?

Thanks,

Ed. Thanks for the nice comments. My stuff goes along with my mindset: this fall I will return to soldering brass tank cars. Last year was more about weathering, and winter of 2020 was the cranes stuff (my 18000 is yet to be completed, and the LR1750 requires a new pivot gear design). I very seldom do hobby stuff during the summer: I go vacation with my family, then enjoy the outdoors, as we don't have long summers here in the Northeast Canada. About the blades, I have cut them out of PVC piping (4" diameter) which is also what I used as a mast: https://www.homedepot.ca/produit/ipex-homerite-products-tuyau-d-ftegout-en-pvc-solide-ecolotubemd-4-inches-x-10-ft/1000421825PVC pipesI randomly designed the shape and cut it using a zip cut blade (messy job BTW!), then sanding the edges. For some reason (I was told the US based plant was totally destroyed by a fire or tornado, or else during the pandemic) , those happen to be difficult to find in retail stores nowadays. Unless you have good contacts with contractors. About the cranes drums, indeed that are micro motors inserted within the drums (found on Aliexpress back then: good luck with China now) but also for all other functions: Micro motorsI used 12v, but that's up to what you can find, and you need several of these in different transmissions setups and RPM depending of the application. I would have to explain to you the electrical layout so to have variable speed as mines, for smooth operation. For those wondering, the LR1300 has never been motorized and was sold to a collector from Jacksonville FL a few years ago. Good luck with your project. As as we usually say here: please post pictures! Stef

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/4/2005

Posts: 983

Location: england

|

Nice.Looks good.I have seen various types of blade handling,lifting holders,whatever they are called.They all position the blade,hydraulically,but that is definitely the biggest,the first one with a ladder,and platform.Is that a model of a specific piece of kit?Either way,it looks really good.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

modelmaniac wrote:Nice.Looks good.I have seen various types of blade handling,lifting holders,whatever they are called.They all position the blade,hydraulically,but that is definitely the biggest,the first one with a ladder,and platform.Is that a model of a specific piece of kit?Either way,it looks really good. I believe they call this a blade yoke. You may wish to take a look at the Liftra website under products, then Liftra LT870-1 Blade Yoke: https://liftra.com/products/lt870-blade-yoke.htmlBlade yoke  bladeyoke_1 bladeyoke_1 by Ironstef70, sur Flickr "/> I did this custom project back in winter 2016. It is a mix of steel/brass components assembled with epoxy adhesive:   IMG_20160205_181720671 IMG_20160205_181720671 by Ironstef70, sur Flickr "/>   IMG_7883 IMG_7883 by Ironstef70, sur Flickr "/> And the windmill was a 2015 project in its first version, with decals. It is fantasy, not reproduced from a prototype:   IMG_6335 IMG_6335 by Ironstef70, sur Flickr "/> Stef

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/4/2005

Posts: 983

Location: england

|

Well built.Really enhances the look of that crane.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

modelmaniac wrote:Well built.Really enhances the look of that crane. Thanks MM. I always like the idea of having realistic accessories and dios to enhance the looks of my models. Now digging into these pictures, I can't wait to return at my workbench as the leaves will soon start falling  Cheers! Stef

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/12/2012

Posts: 164

Location: Fayetteville, NC

|

Ironstef70 wrote: About the blades, I have cut them out of PVC piping (4" diameter) which is also what I used as a mast: https://www.homedepot.ca/produit/ipex-homerite-products-tuyau-d-ftegout-en-pvc-solide-ecolotubemd-4-inches-x-10-ft/1000421825PVC pipesI randomly designed the shape and cut it using a zip cut blade (messy job BTW!), then sanding the edges. About the cranes drums, indeed that are micro motors inserted within the drums (found on Aliexpress back then: good luck with China now) but also for all other functions: Micro motorsI used 12v, but that's up to what you can find, and you need several of these in different transmissions setups and RPM depending of the application. I would have to explain to you the electrical layout so to have variable speed as mines, for smooth operation. Stef, Thank you for your response. I never even thought of cutting the blades out of the PVC pipe. very creative! As for the motorized hoists, I have bought a number of those micro motors a while back, but I am very interested in how you mechanically linked the motors to the hoist drums and were the drums reused from the crane or did you make new drums? Thanks, Ed.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

allisoes wrote:Ironstef70 wrote: About the blades, I have cut them out of PVC piping (4" diameter) which is also what I used as a mast: https://www.homedepot.ca/produit/ipex-homerite-products-tuyau-d-ftegout-en-pvc-solide-ecolotubemd-4-inches-x-10-ft/1000421825PVC pipesI randomly designed the shape and cut it using a zip cut blade (messy job BTW!), then sanding the edges. About the cranes drums, indeed that are micro motors inserted within the drums (found on Aliexpress back then: good luck with China now) but also for all other functions: Micro motorsI used 12v, but that's up to what you can find, and you need several of these in different transmissions setups and RPM depending of the application. I would have to explain to you the electrical layout so to have variable speed as mines, for smooth operation. Stef, Thank you for your response. I never even thought of cutting the blades out of the PVC pipe. very creative! As for the motorized hoists, I have bought a number of those micro motors a while back, but I am very interested in how you mechanically linked the motors to the hoist drums and were the drums reused from the crane or did you make new drums? Thanks, Ed. Indeed the motorized hoist drums were all custom made so to have the motors inserted inside. I could almost rebuild the LR1750 with its original parts (except the pivot) as I have kept all parts. I would have to transfer a few pictures to my hosting site and continue this post. Maybe later this week. Stef

___________________________________________________ Playing with toys since 1970, now building them.

|

|

|

Guest |