|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

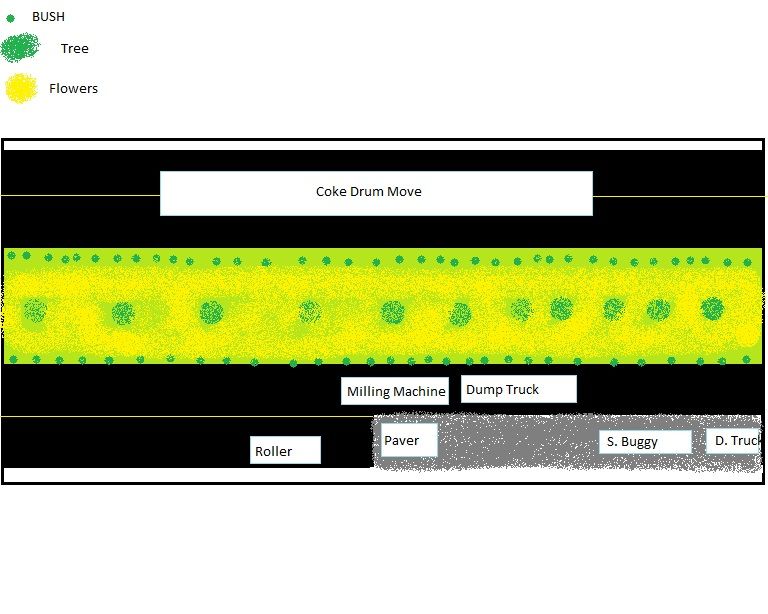

2/16/14 UPDATE Ok guys, all the materials and models are here. Time to get this show on the road. I really want this to turn out nicely so I am going to need your expert opinions  First thing to discuss is the layout. I have about a 70" x 20" area to work with. In this area I want it set up like an interstate. 2 lanes in each direction with a median dividing the two directions. One direction will be set up as a paving operation with RoadTec equipment and support equipment that you would see on a real work site. The other highway direction will have Mammoet moving a Coke Drum. I would love to figure out a way to display the paving operation with a resurfacing part as well as a new paving part complete with gravel base being laid by the crew. What are your thoughts? Any pics similiar to what I am describing? Feel free to chime in and help.

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/20/2014

Posts: 352

Location: South of VA, North of SC

|

good plan! I would put something in the median, like an excavator digging up a busted water main! the dirt side must infect everything!

...Dylan My Instagram: Cat330DL_Man

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

Cat336EL wrote:good plan! I would put something in the median, like an excavator digging up a busted water main! the dirt side must infect everything!  I like it. Maybe put down a 1" thick sheet of styrofoam board across the whole base, then the grass mat, then everything else? Would make it easier to make trees stand and set their heights as well I suppose.

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/1/2008

Posts: 305

Location: Retsof

|

If you added 2" foam it would allow you a approx. 8ft excavation in the grass area if you wanted to dig a water main repair. Just a thought.

Wes

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/20/2014

Posts: 352

Location: South of VA, North of SC

|

EastCoastFabricator wrote:Cat336EL wrote:good plan! I would put something in the median, like an excavator digging up a busted water main! the dirt side must infect everything!  I like it. Maybe put down a 1" thick sheet of styrofoam board across the whole base, then the grass mat, then everything else? Would make it easier to make trees stand and set their heights as well I suppose. yep! that's how I traditionally build dioramas!

...Dylan My Instagram: Cat330DL_Man

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

Here's the progress so far. Trying to figure out the layout as well as how to fit all the models in the case. If anyone is interested, the case is 6 feet wide and around 4 feet tall from Stamps Store Fixtures and runs around $270 if you're looking for one  As always comments and ideas are welcomed!!

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

Today's progress:

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/5/2007

Posts: 2,774

Location: Sarasota, Florida, USA

|

One thing I see is that all milling operations usually are performed before the paving is done. The reason is that they don't want millings contaminating the paving area. Here where I live they did a "mill and fill" operation back in 2012. They milled the road one lane at a time (our road here is a six lane with median and turn areas), they started with the outside lane first and went thru with 3 milling machines, then they came thru with a skidsteer with a milling head for small areas like manholes, then they swept the milled surface with a tractor broom and street sweeper, then they came thru with the asphalt distributor and sprayed a tack coat, then the paving train came thru which had a transfer buggy and paver and then 2 steel drum rollers with vibration and then 1 rubber tired finish roller. The whole operation stretched about a half mile. Then once the outside lanes were done they did the center lane then the inside and left turn lanes. Took them about 2-3 weeks (actual work time was about a week but extra time was due to rain) to do both sides (east bound and west bound) for a distance of I think it was 10 miles of road.

Oh and you don't want your ADT running in the median as it will kill the vegetation and might get stuck. Other than the milling machine and dump truck placement it looks really good, also might want to add a crossover from one set of lanes to the other which would also be in real operations like that.

Dain

I'm a kid at heart, so I will play with any model construction vehicle from 1:87 scale to 1:1 scale!!!!

Age is a state of time NOT a state of mind!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

dain555 wrote:One thing I see is that all milling operations usually are performed before the paving is done. The reason is that they don't want millings contaminating the paving area. Here where I live they did a "mill and fill" operation back in 2012. They milled the road one lane at a time (our road here is a six lane with median and turn areas), they started with the outside lane first and went thru with 3 milling machines, then they came thru with a skidsteer with a milling head for small areas like manholes, then they swept the milled surface with a tractor broom and street sweeper, then they came thru with the asphalt distributor and sprayed a tack coat, then the paving train came thru which had a transfer buggy and paver and then 2 steel drum rollers with vibration and then 1 rubber tired finish roller. The whole operation stretched about a half mile. Then once the outside lanes were done they did the center lane then the inside and left turn lanes. Took them about 2-3 weeks (actual work time was about a week but extra time was due to rain) to do both sides (east bound and west bound) for a distance of I think it was 10 miles of road.

Oh and you don't want your ADT running in the median as it will kill the vegetation and might get stuck. Other than the milling machine and dump truck placement it looks really good, also might want to add a crossover from one set of lanes to the other which would also be in real operations like that. Thanks for the advice! Im trying to keep it as realistic as possible but its hard due to the space I have to work with. How would you lay it out based on the last pic I added? can rearrange anything at this point.

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/29/2014

Posts: 231

Location: VA

|

Is this a two way Road seperated by a median? If so, wouldn't you have to turn the Coke Drum Move around so it is going the opposite way?

Patrick

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/29/2014

Posts: 231

Location: VA

|

Sorry, double post

Patrick

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

the coke drum set will go from right to left while paving from left to right.

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/3/2013

Posts: 744

Location: North Wales, UK

|

Looks fantastic, good job! Its nice to display model in some sort of dio. I have mine in a glass cabinet and some are sat on some gravel. looks so much better!

New UK based Scale construction forum. www.scaleplantandconstruction.co.uk

|

|

|

Guest |