|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/19/2013

Posts: 764

|

AAAAAAAAAAAAAAAAAAAAAAAAAA-MAZING!!!!! Can you build two? One to leave bare metal and one to paint?

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

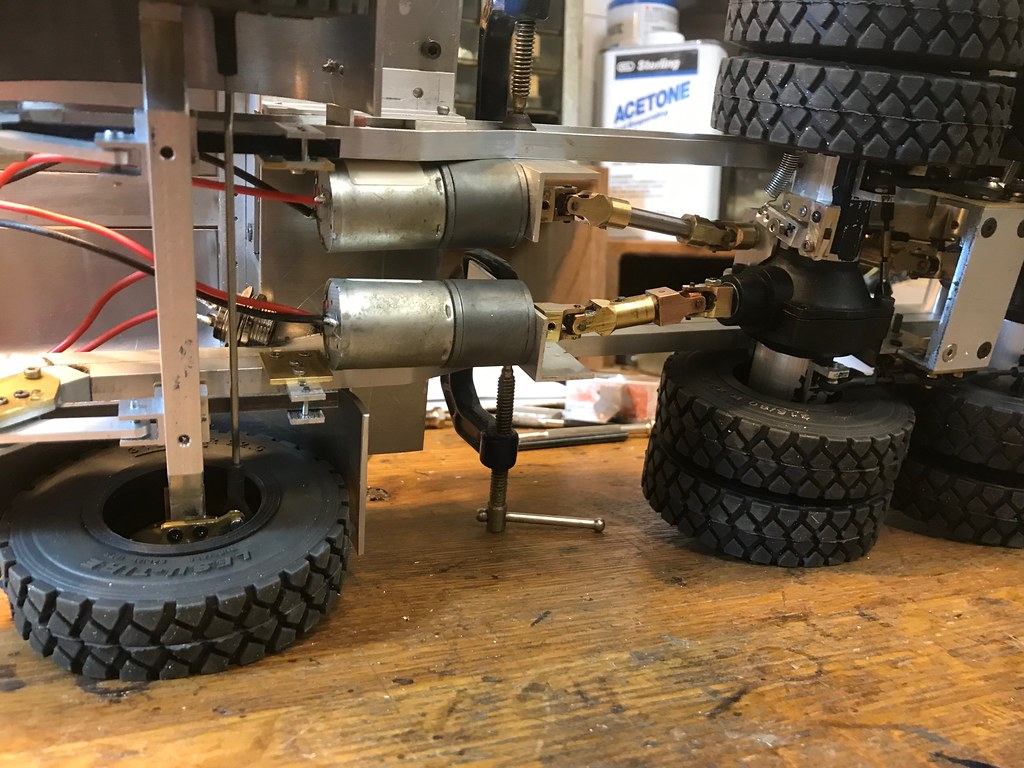

Small update on the Euc. I didn’t have much time lately for a variety of reasons, including a bad cold that kept on coming back. But I managed to get the drive shafts done. I installed 2 temporary gear motors and that gave me the opportunity to test the truck and worked out some problems in the drive axles.     Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/4/2005

Posts: 990

Location: england

|

Looks really,really good  Love them wheels!

|

|

Rank: Advanced Member

Groups: Member

Joined: 7/6/2015

Posts: 1,317

|

Kerst that looks fantastic

Steve

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/8/2002

Posts: 789

Location: Clevedon UK

|

Given that the rear axles are not driven off a common drive, how are you going to match the axle speeds?

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/13/2005

Posts: 1,321

Location: Latrobe,Pa.

|

Wow very nice detail. Planning, and plans,I cant imagine!

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

Mark Bridle wrote:Given that the rear axles are not driven off a common drive, how are you going to match the axle speeds? This is a temporary setup. It will have one motor with a 4-speed gearbox. Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

I did some work on the Euc. I installed a Mabuchi 555 12V DC Motor, which seems to have sufficient power for this truck. And I built a temporary reduction box, so that I can drive it around and get a sense of the speeds. later I will build the final gearbox. I tested the Euc in the dirt and took some videos: https://youtu.be/V9AssoKzzBIhttps://youtu.be/zraLPbm_xeMKerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/18/2003

Posts: 2,254

Location: Charlotte, North Carolina

|

I would have given up the "left one" to be as talented as you. That is so fantastic. Keep up the pictures and content for us. CAW

|

|

Rank: Advanced Member

Groups: Member

Joined: 7/6/2015

Posts: 1,317

|

Kerst that is fantastic as the Q said very talented. Can not wait to see that monster finished and painted.

Steve

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

I tried a simple mechanism for the tipping. It is basically a geared motor with a small winch pulling a lever, which does the tipping. This is the first try and I managed to lift it with a 11 lbs load. Not bad. Now I can work out the details. Here a video: https://youtu.be/CMy56WsefUkKerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/13/2005

Posts: 1,321

Location: Latrobe,Pa.

|

Impressive work. Thanks for sharing.

|

|

Rank: Advanced Member

Groups: Member

Joined: 7/6/2015

Posts: 1,317

|

Very nice work.

Steve

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/14/2006

Posts: 762

Location: Arizona

|

AWESOME work! Thanks for sharing.

Best Regards, Randy

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

I had the chance to try it out at the Cabin Fever Expo in Lebanon, PA. Here a video of the Euc in action: https://youtu.be/0ddt3ukXhLIKerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 7/6/2015

Posts: 1,317

|

That’s incredible, I can’t wait to see that that in Euclid green. Great action video of that monster.

Steve

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/2/2005

Posts: 648

Location: America

|

Not the dump mechanism I was expecting to see, but it's still brilliant engineering. Bravo Kerst!

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

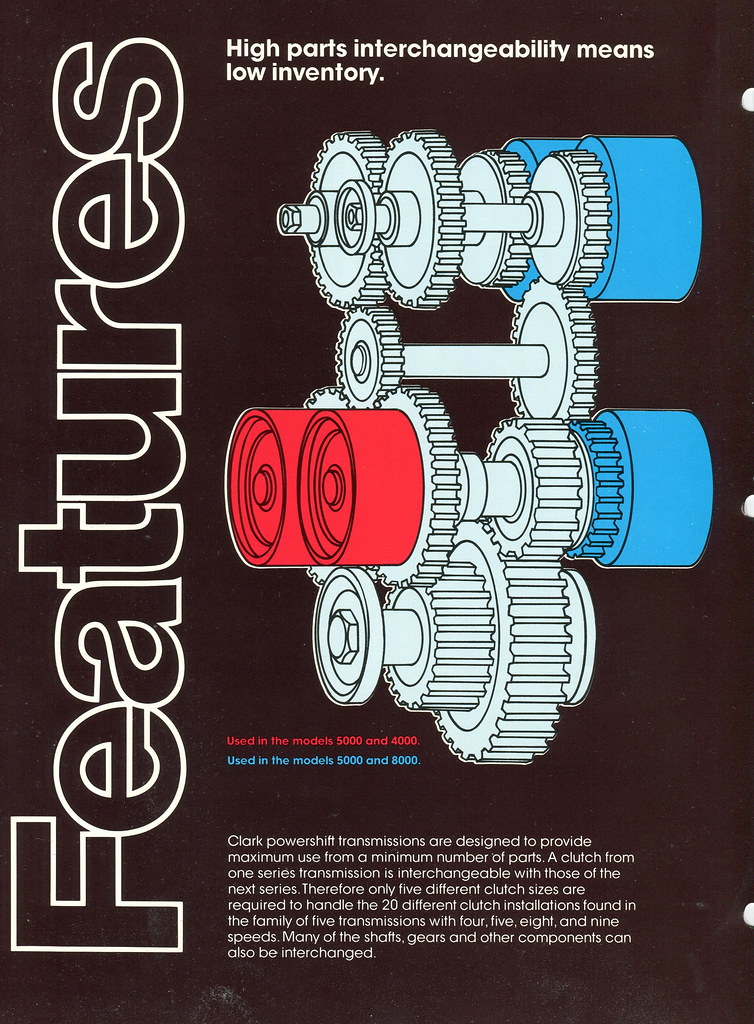

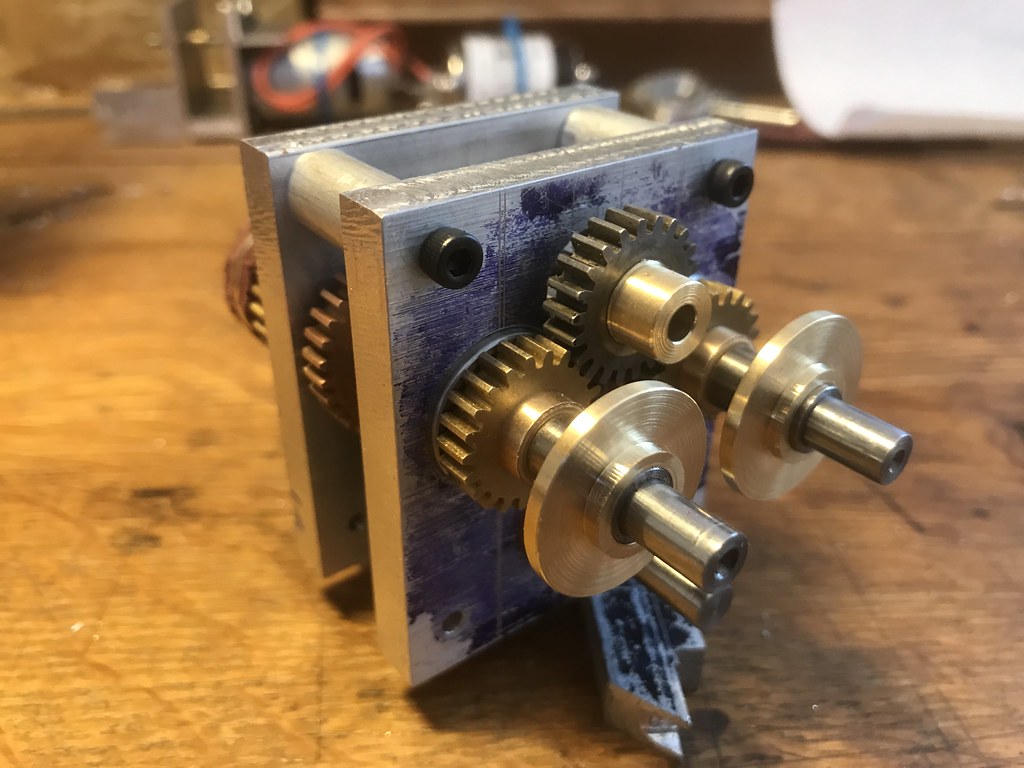

I have been working on the power-shift transmission. This is an experiment and needed some proper preparation, including calculating ratios, making accurate drawings, etc. Quite the challenge! The Clark series 6000 is the example.   I omitted the forward/reverse clutches. An electric switch can take care of that and it saves space.  I use leather as clutch material.   The middle shaft on the left is the input shaft and I still need to figure out how to connect that to the motor, an 540 CRAWLER BRUSHED MOTOR 80T. I am still making all the components and I am not sure if it all will work. Making the frame demanded a lot of accuracy. My Southbend was up to it! I did a lot of measuring at every stage to make sure things will fit OK.  So far so good. I plan to control the clutches with 2 servos. W'll see how that works out! Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/18/2007

Posts: 1,025

Location: South of the Weminuche

|

|

|

|

Guest |