|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/14/2011

Posts: 191

Location: Massachusetts US

|

What a massive project! Looks great.

My Photostream

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/14/2010

Posts: 393

Location: ste. anne manitoba canada

|

that is super wicked ... really like the shackles you made ... excellent work ... larry

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/30/2006

Posts: 889

Location: Las Cruces, NM

|

I really enjoy following your threads on this project. What a sight it must be in all of its stages!! As far as your copper sleeves, it sounds like you need a proper swaging tool. I have always purchased my tools and sleeves here: Stage Rigging Online or Fehr Brothers I hope you find these useful. Dan

1:1 or 1:50, I am still in awe.

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,154

Location: Copake, NY

|

It is beautiful! WOW! Nice to see it coming together! Thanks for the update, Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/2/2007

Posts: 5,966

|

now that is some impressive craftsmanship!!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

Thank you guys. I boomed it up and held the cable with some clamps to see how everything looked. I pulled down on the point and was able to tilt the rear of the machine up without any problems. Every time I have the brass boom up in the air I'm very nervous it could come crashing down  I'm going to need to add about 20# in the rear of the revolving frame now because the front lip on the tub is dragging too hard making walking a bit difficult.When we had it out in January digging at a show I noticed this problem and the rear seemed light when I had a full bucket out towards the point. Hope to have every thing in order in the next couple evenings because I'll be taking this up to the Lakeside Sand and Gravel open house this Sunday. Here's a view from the house roof:  Boom Up:

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

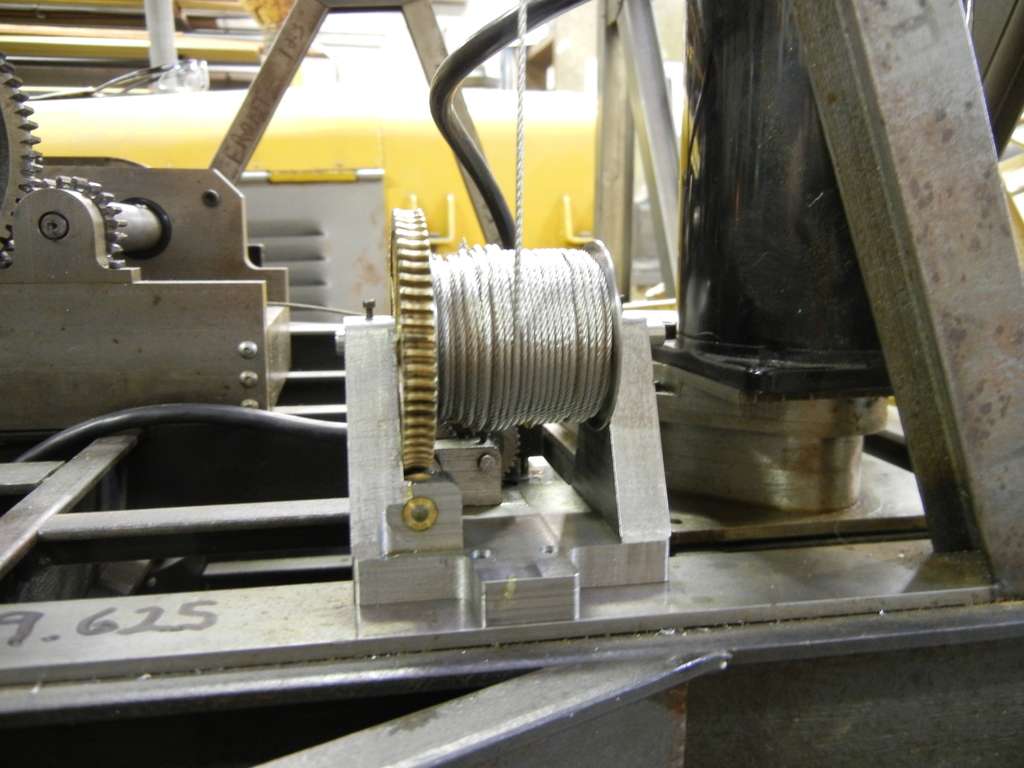

mixontour wrote:I really enjoy following your threads on this project. What a sight it must be in all of its stages!! As far as your copper sleeves, it sounds like you need a proper swaging tool. I have always purchased my tools and sleeves here: Stage Rigging Online or Fehr Brothers I hope you find these useful. Dan Thanks for the link. I ordered a set of swage pliers the other day. Today I finally got the boom hoist attached to the machinery deck and was able to boom up under power for the first time. Tiny 0-80 set screws  I wish I would have had a sharper endmill when I made the hoist,My new camera picks up all the bad details:o  A full drum of cable.  While getting the drag ready for Sunday I decided to drill and tap the drag jaw clutch bolts. When I'm pulling in hard it would slip because it was only pressed in. Now we'll have to watch we don't pull too hard digging because the only weak point is the motor coupling. Or it may just drag the whole machine into the pit:p Complete load unit. And walking pinion.  Tapered lock bushing I made to lock the gear to the shaft.  Exploded view  Bearings

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/24/2006

Posts: 2,185

Location: Grapevine, Tx

|

This is going to be an amazing model!!!!! Great craftsmanship for sure 9wbucyrus!!!!!!!!!!!

Jeff

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/27/2010

Posts: 1,905

|

This is craftsmanship at it's finest !!!! Can't wait to see the end result.

“A tiger doesn't lose sleep over the opinion of sheep.” ― Shahir Zag

" An educated mind learns from his mistakes and corrects them. A dolt, on the other hand, lashes out and continues showing his ignorance."

-Unknown

“Two possibilities exist: either we are alone in the Universe or we are not. Both are equally terrifying.”― Arthur C. Clarke

"Anti-social behavior is a trait of intelligence in a world full of conformists" - Nikola Tesla

" If you think it's expensive to hire a professional to do the job, wait until you hire an amateur ". Paul Neal "Red" Adair {Wild Well Firefighter for those who live under rocks}

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/14/2006

Posts: 667

Location: The Netherlands

|

Hi Steve No words just      Think it's time for some youtube action , love to see a movie that it's booming up. I know that feeling of being a bit nervous when you have the boom up in the air. It will get less after a few years but it never disappears completely. Thanks for this super post again. Eef

*** Flickr American cranes group*** 3D printed crane parts at I.materialise

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/21/2003

Posts: 756

Location: Athens, Alabama

|

Great model, and your machining skills are great.

Regards, Colin

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

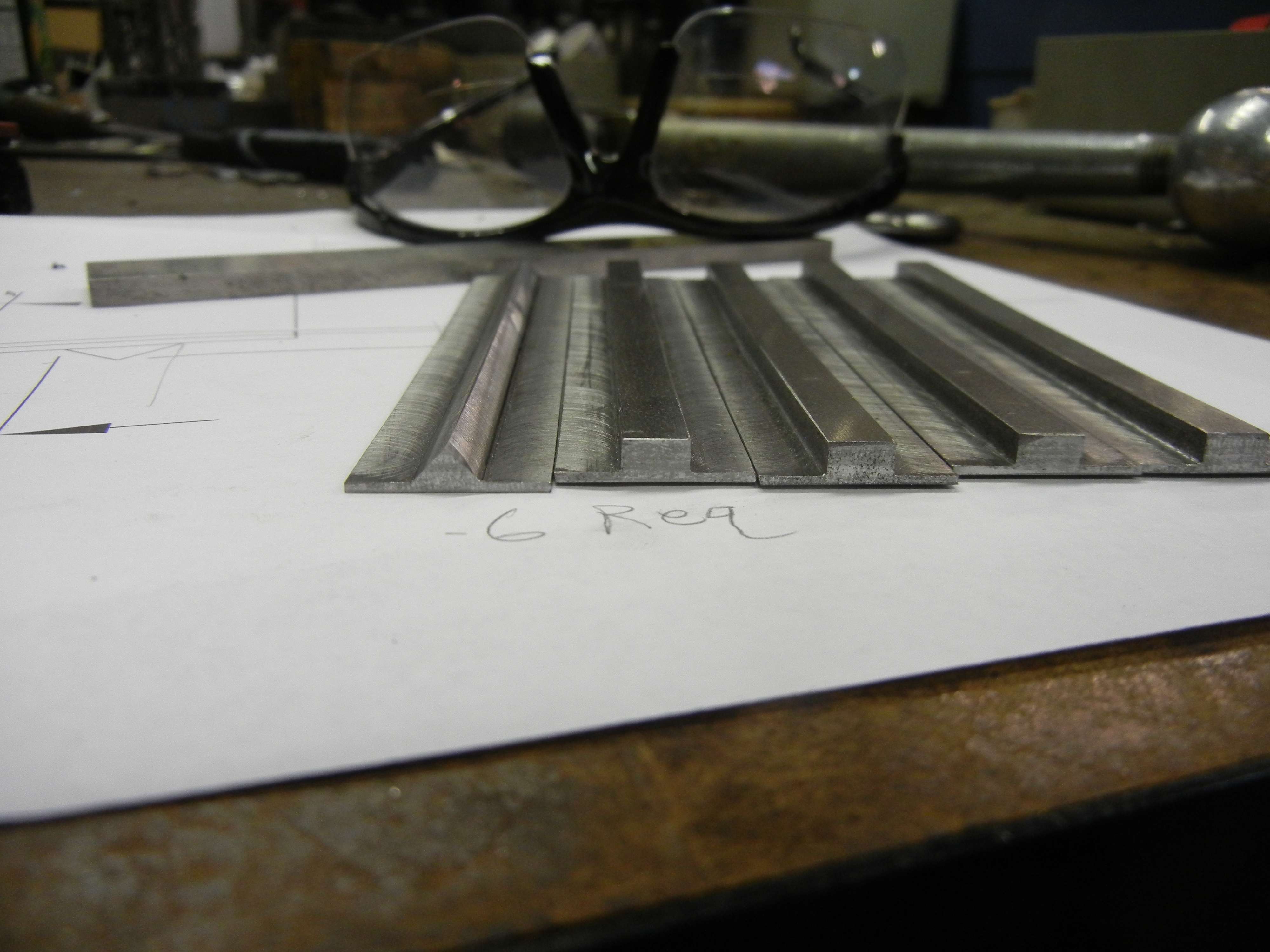

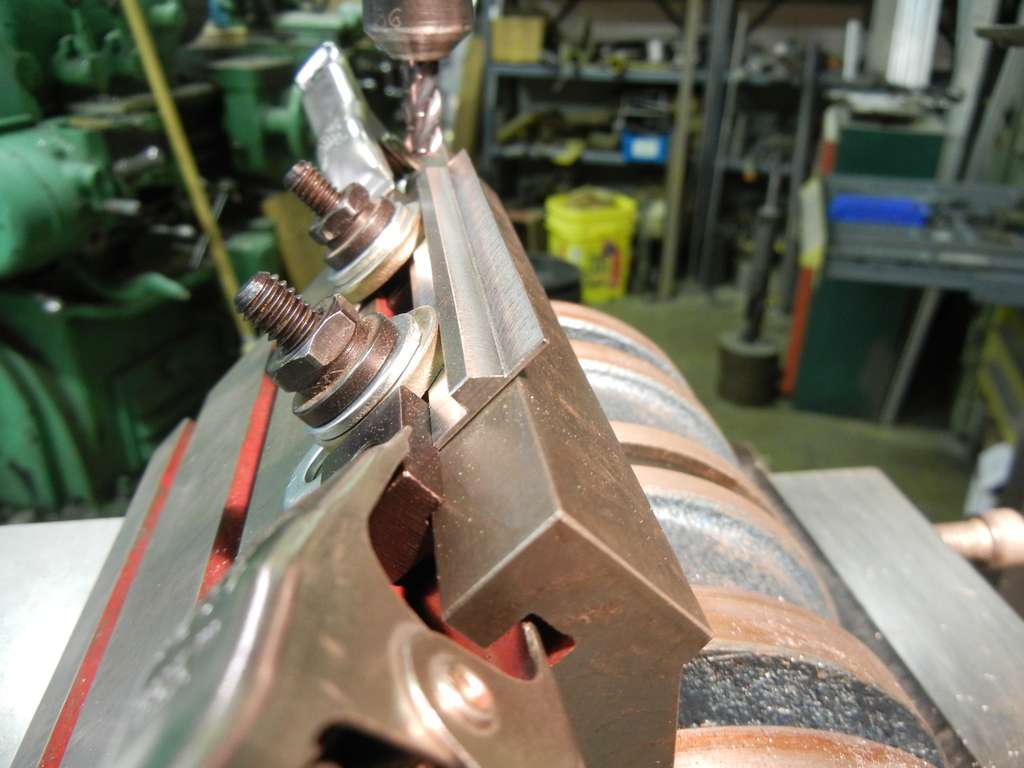

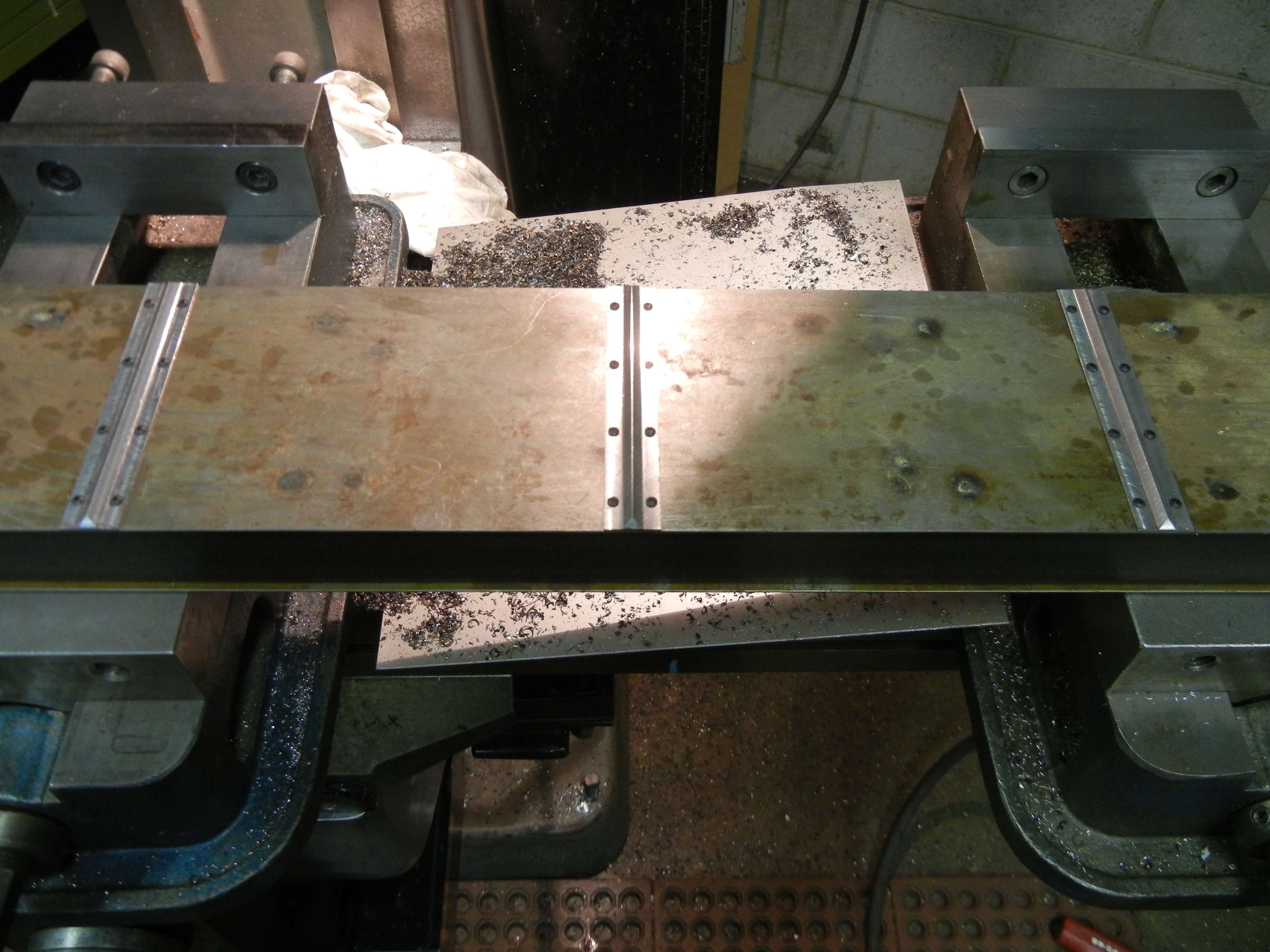

I haven't done much lately on the 9W but, here is my progress on the walking shoe cleats. I had to get these machined out and attached so we can take the dragline out to our steam show on the 12th of August. It needs some traction to walk. I think now we'll be able to walk up a 10% grade. Definitely on level ground too. I should add about 15-20lbs ballast in the rear of the revolving frame to compensate for the boom now installed because the edge of the tub is somewhat heavy and not sliding along easily while walking.:cool: Roughed in pieces:  Cutting a 45deg. bevel:  Beveling the ends:  Attached with #1-72 screws:   Ready to walk again:

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/26/2008

Posts: 534

Location: West Coast

|

amazing!! theres not much I can say that hasn't already been said numerous times.. It really is a masterpiece! I enjoy this build and the LTM-1800 so much! keep up the great work, im excited to see it when done

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Outstanding! Do the real machines have cleats on the walking shoes or is the weight alone enough to move the real things? Thanks for the updates. Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/18/2008

Posts: 515

Location: Richfield, Oh (Cleveland)

|

"Bleeping" REMARKABLE Steve!

What a great effort.

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

Thanks again for the kind words you guys. RowanH Yes, All draglines have cleats on their shoes. Just think without them you would have one big toboggan sliding  . The tub is smooth and that's another problem. I had a guy comment on another site one time telling me that the mine boss was too cheap to build the road the proper grade and they were walking a machine up in the rain, and he said a couple times when he took a step and set back on the ground the machine slid down hill a few hundred feet only to stop when it hit the berm on the edge  I guess he had to call his wife to bring him some clean britches  Here's a picture from an old 1930's Monighan drgline.

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

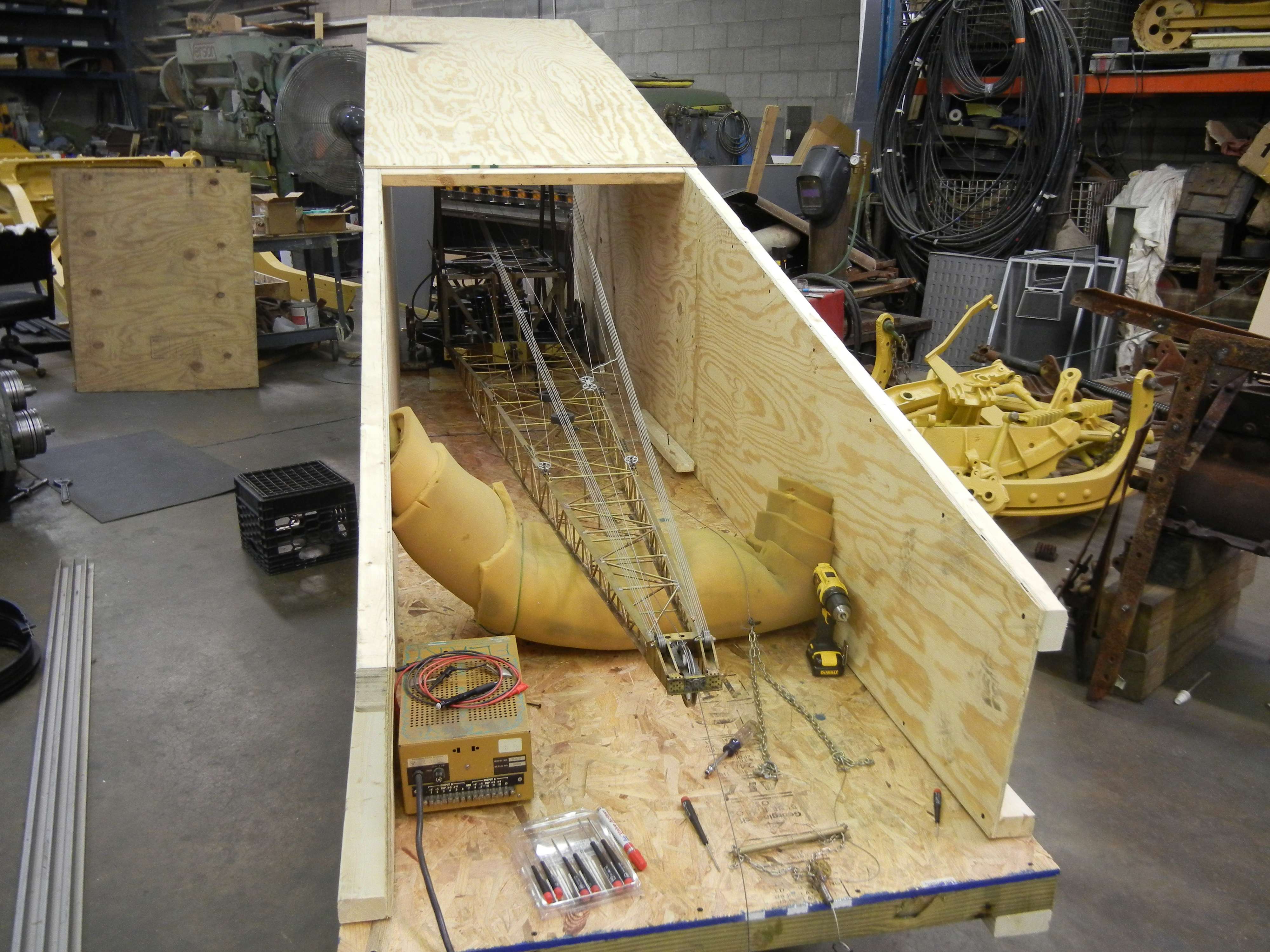

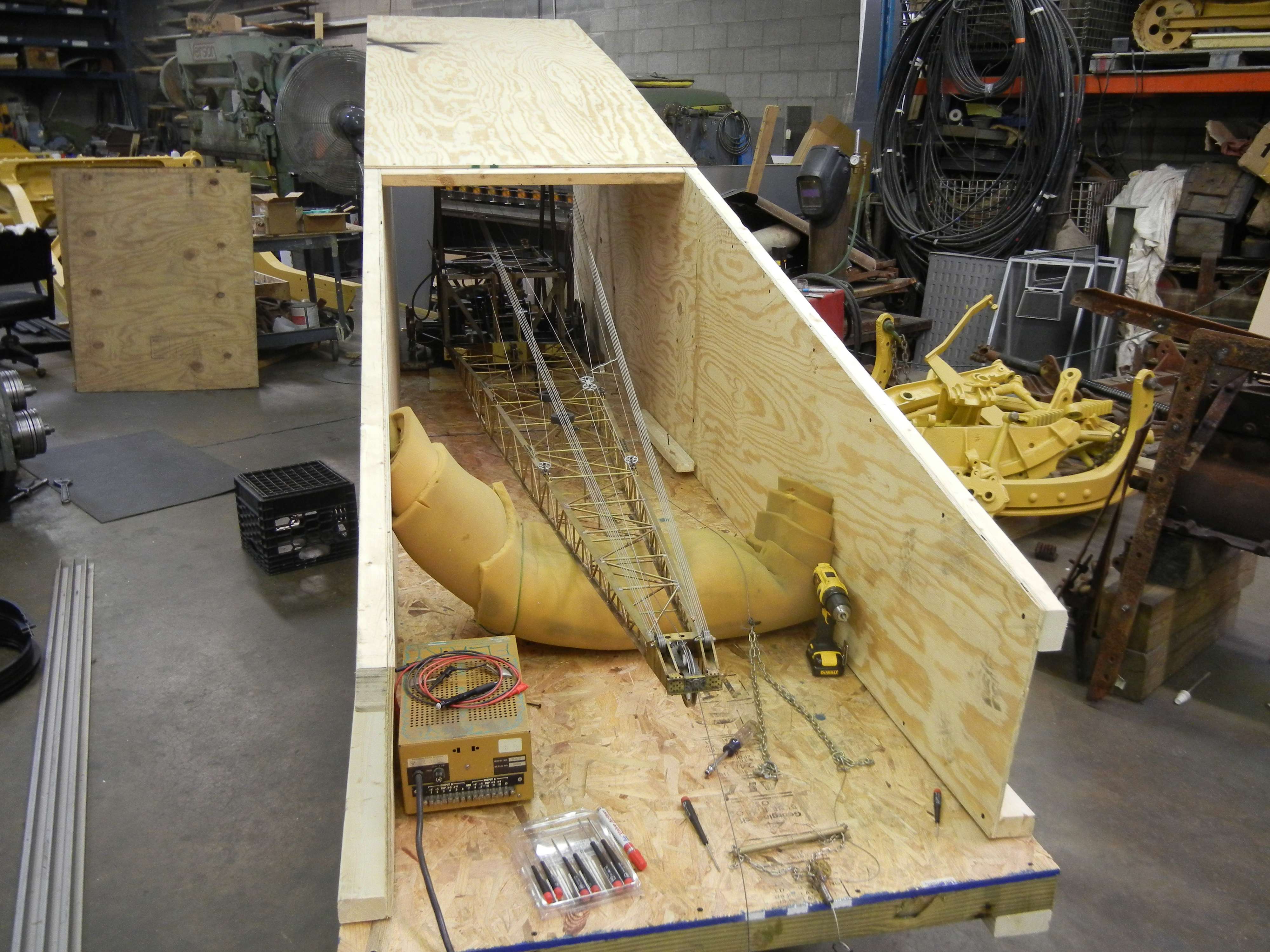

Getting ready for this weekend's antique equipment show for another "BIG DIG" I finally took the time to build a suitable shipping box for my machine. It measures 174''x40''w x 48''h. Now I'll be able to haul it on my gooseneck trailer with some other stuff.  I want to put some eyebolts on the sides to hook a bungee cord to give the boom a cradle for a cushion ride.  Another quick fix was to break some welds on the bucket so I could bend the teeth down a few degrees to give it a better bite. This is still going to be a temporary bucket till I can fabricate a better replica. A quick set up in my press brake did the trick:

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/5/2008

Posts: 693

Location: Pittsburgh,PA

|

Getting ready for this weekend's antique equipment show for another "BIG DIG" I finally took the time to build a suitable shipping box for my machine. It measures 174''x40''w x 48''h. Now I'll be able to haul it on my gooseneck trailer with some other stuff.  I want to put some eyebolts on the sides to hook a bungee cord to give the boom a cradle for a cushion ride.  Another quick fix was to break some welds on the bucket so I could bend the teeth down a few degrees to give it a better bite. This is still going to be a temporary bucket till I can fabricate a better replica. A quick set up in my press brake did the trick:

9W Walking Dragline Build Links:http://www.rctruckandconstruction.com/showthread.php?t=117Scale 4x4 RC Buildhttp://www.youtube.com/user/Scentlessapprentice9?feature=mhee#p/u/9/59FR27c9BwEhttp://imageshack.us/user/caffco

|

|

|

Guest |