|

|

Rank: Advanced Member

Groups: Member

Joined: 2/27/2006

Posts: 1,298

Location: Somewhere in the USA

|

This thread is worthless without pics. I don't have the 1300 but if we had a pic we might be able to come up with something.

There are two rules for success: 1. Never tell everything you know.

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/8/2002

Posts: 5,515

Location: New Jersey

|

Use a thin steel tube over the largest diameter (diagonal) and make 4 flats by vise ! Drill small hole in tube insert a pin and then you have a key !

Chet

I live in my own little world it's ok they know me here

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/29/2010

Posts: 1,916

Location: Maine U.S.A

|

VIPCranes wrote:Even on my 11200 the same problem happened. Happened on mine to on the luffer drum

-Mike

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/11/2007

Posts: 9,039

Location: Lincolnshire

|

CAT324DL wrote:VIPCranes wrote:Even on my 11200 the same problem happened. Happened on mine to on the luffer drum  On one of mine too, but it is not a big deal on the LTM 11200-9.1 as you can easily turn it by hand. Looks like I will have to be very careful with my LR1300 in future! Paul R

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/5/2008

Posts: 188

Location: Holland

|

Robert Heuston wrote:The A frame line on my LR1300 is tangled around the spindle that the drum is on. When I get home I'm going to have to try and de-rig the a frame and un tangle it all. I feel your pain bro

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/23/2010

Posts: 1,734

Location: Hunter Valley

|

cranboyrick wrote:Robert Heuston wrote:The A frame line on my LR1300 is tangled around the spindle that the drum is on. When I getad I'm not the only one. home I'm going to have to try and de-rig the a frame and un tangle it all. I feel your pain bro   Glad I'm not the only one.

|

|

Rank: Advanced Member

Groups: Member

Joined: 7/22/2011

Posts: 207

Location: Trenton ohio

|

Oh your guys drums are yellow?? Mine are a grey color is mine older or newer I wonder.

Steel makes the world go round that is why I pride my self with the work I do. I am a proud steel mill worker.

Dan

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

mine are grey as well, i think this one is a V.Marjwik livery or however you spell it

Brandon my youtube channelMy Facebook Page

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/2/2007

Posts: 5,966

|

i want that V Marwjik version badly!

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/11/2007

Posts: 9,039

Location: Lincolnshire

|

DeWoc19 wrote:i want that V Marwjik version badly! Just to keep you going Zach:  Paul R

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/5/2007

Posts: 2,774

Location: Sarasota, Florida, USA

|

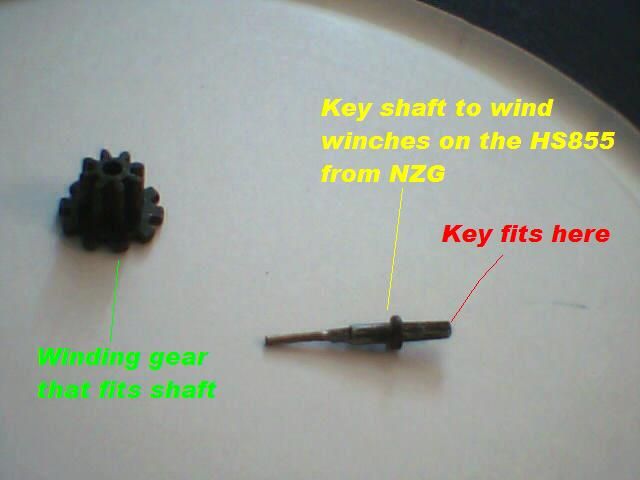

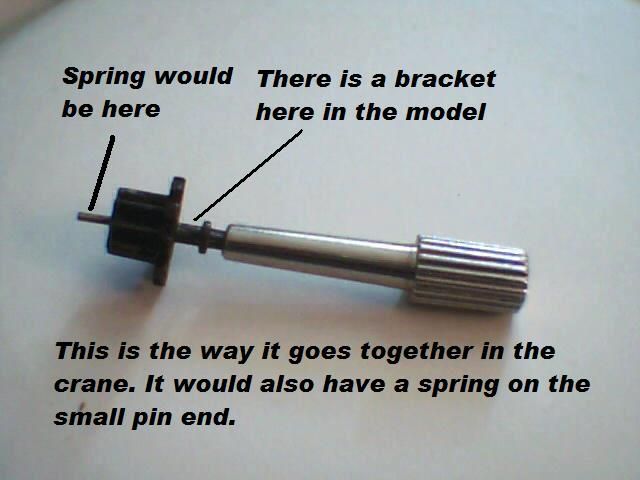

I've had somewhat the same issue with my 855. The shaft thing the key goes on has a small wire like end with a spring over it. It has come out of the winding mechanism and the wire like end has broken off. I used a small drill bit (1/32) and drilled it out some then I JB welded a piece of stiff wire in it and reassembled the thing. Only problem I have right now is it popped back out. I have to take it apart again to fix it but until I get the gumption to do it I use my finger to wind it and I also have a wood ick to jam it so it won't unroll itself especially when I have it set for dragline work. No NZG does not have the spare key shaft which is sad but it will create a business for someone, now if I only had a Micro Lathe like I want       !!

Dain I'm a kid at heart, so I will play with any model construction vehicle from 1:87 scale to 1:1 scale!!!! Age is a state of time NOT a state of mind!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/2/2007

Posts: 5,966

|

you know that cruel and unusual punishment right Paul!? you are a cruel man

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/11/2007

Posts: 9,039

Location: Lincolnshire

|

DeWoc19 wrote:you know that cruel and unusual punishment right Paul!? you are a cruel man Yes,I know

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/5/2007

Posts: 2,774

Location: Sarasota, Florida, USA

|

I got some shots of the pin shaft part that breaks on the NZG cranes for anyone who wonders what they are. This is the "exploded" view, the shaft is the part that breaks on the small end opposite where the "key" fits on. In this first picture I have drilled out the broken end (very hard and frustrating) by hand and fit a piece of wire in it and JB Weld was used to secure it.  This is how it is supposed to go together in the crane.  NZG will not replace the shaft for some reason and it is basically the only part that fails in the cranes. If I had a micro lathe I would see about making some to sell as it is not all that hard to design a new one. Hoe this helps some who are wondering what is trying to be described.

Dain I'm a kid at heart, so I will play with any model construction vehicle from 1:87 scale to 1:1 scale!!!! Age is a state of time NOT a state of mind!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

I don't have any cranes in my collection at the moment but that was a well photographed and explained post Dain. Cheers. Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/5/2007

Posts: 2,774

Location: Sarasota, Florida, USA

|

Thanks Rowan, I figured I'd post the pics to show exactly what was being described.

In these pics the shaft has been drilled and a wire piece was put in place with the 2 part JB Weld epoxy stuff. I just have to pull the crane apart one of these days and repair it. This is off the front winch which is used for the fair lead to the dragline bucket. The 2nd winch also needs repair as it has started to be fiddly.

My significant other has the Liebherr HS855 in Busker colors and when I rewound the winches with Musky Master the shafts on it messed up like on my 855.

I just wish I had the equipment to machine a better shaft part to sell/give to others.

Dain

I'm a kid at heart, so I will play with any model construction vehicle from 1:87 scale to 1:1 scale!!!!

Age is a state of time NOT a state of mind!!

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/23/2010

Posts: 1,734

Location: Hunter Valley

|

|

|

|

Guest |