|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

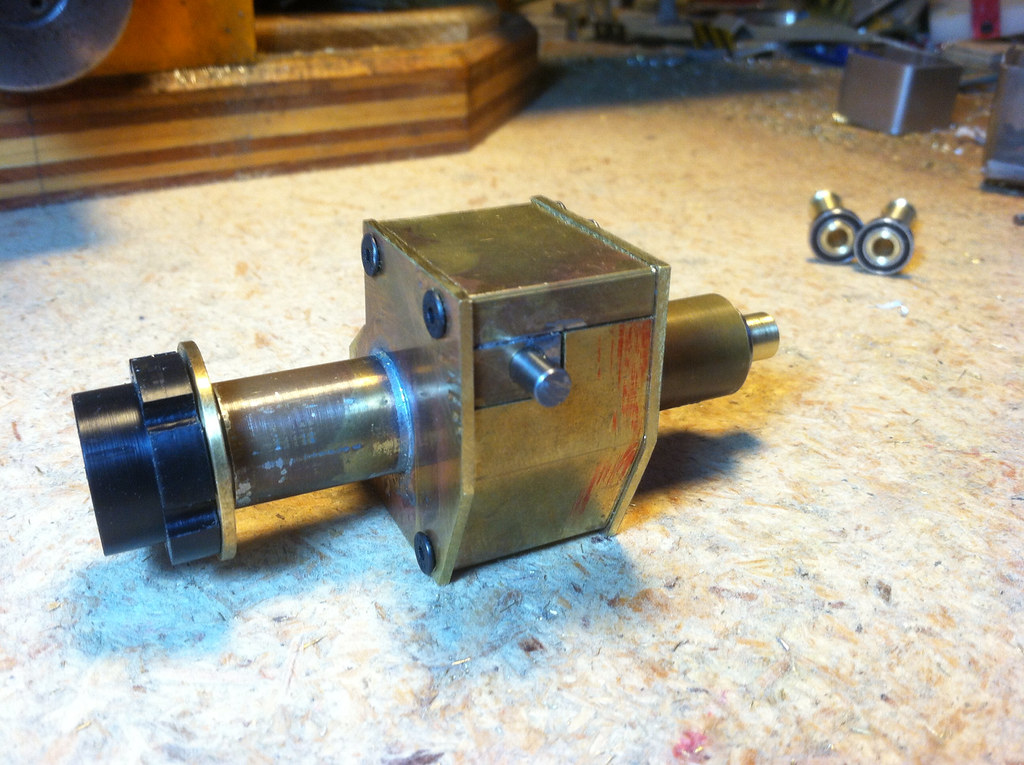

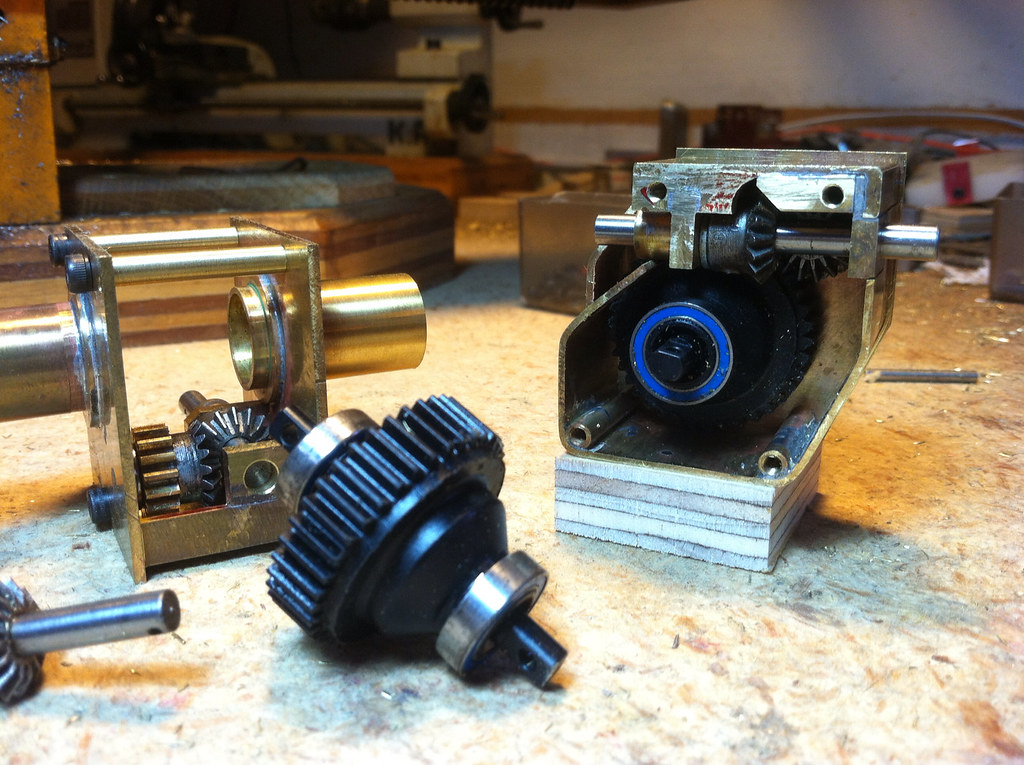

Demag TC 500 truck crane in scale 1/24 Now that the LTM1800 is more or less finished it is time for a new project. I have been thinking about which crane to built for quite a while and I actually started with some parts a few months ago. Before deciding to actually build this crane. It is a German built Demag crane on a Faun carrier and was produced in the late 70’s. There are still some around, one at Inland Crane hire in in Idaho. On this page you can see the TC500 ready for action: http://www.heavyequipmentforums.com/showthread.php?14902-Bridge-replacmentVan Seumeren also had a few: https://www.flickr.com/photos/73498813@N02/6641955839/The Demag TC500 is the successor of the TC400 and is basically the same crane, just a few reinforcements and more counterweight and is rated at 125 metric tons capacity. Here two pictures, one from the back of a leaflet and the other taken by myself. I will build the version with the very low-line carrier cab.    Here are two pictures of the rims:   The tires come again from the All American Toy Company. At the moment I am working on the drive axles, which is a challenge, because space is very limited. I decided to completely build the axles myself. Here are some pictures:   Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/9/2010

Posts: 287

Location: Brisbane ,Australia

|

Great work Krest,

Do you make the gears yourself or have you brought them to fit and built everything around them.

Wayne

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

ozcranedude wrote:Great work Krest,

Do you make the gears yourself or have you brought them to fit and built everything around them.

Wayne Thanks! The gears are bought, then I make them fit. kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 11/11/2006

Posts: 3,421

Location: UK

|

Going to be another good project to watch

Heavy Cranes

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/14/2010

Posts: 113

Location: NQ Aust

|

You said it Jack! Can you post heaps more in-detail progress pics somewhere please Kerst...I am hoping to learn a few tricks of the trade for future projects. Cheers and thanks for sharing.   Happy old fart...Mark

If you only do what you've always done, you will only get what you always got!

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/13/2011

Posts: 1,021

Location: California

|

Definitely one of my favorites treads on the forums. Good job.

SOMETHING IS BETTER THAN NOTHING. http://s1185.photobucket.com/home/vipyfz2008/indexhttp://www.youtube.com/user/vipyfz?feature=mheeluis.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/14/2006

Posts: 667

Location: The Netherlands

|

Hi Kerst Very nice choice , one of the real European classic's. Hope you are gone make the version with the carrier cab like the the one in the first and second picture. The carrier cab in the link is lower and it always looked it bit peculiar to me. ( btw i always thought that the lower cab was only used on the 600/650 ) Looking forward to see the progress. Eef

*** Flickr American cranes group*** 3D printed crane parts at I.materialise

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

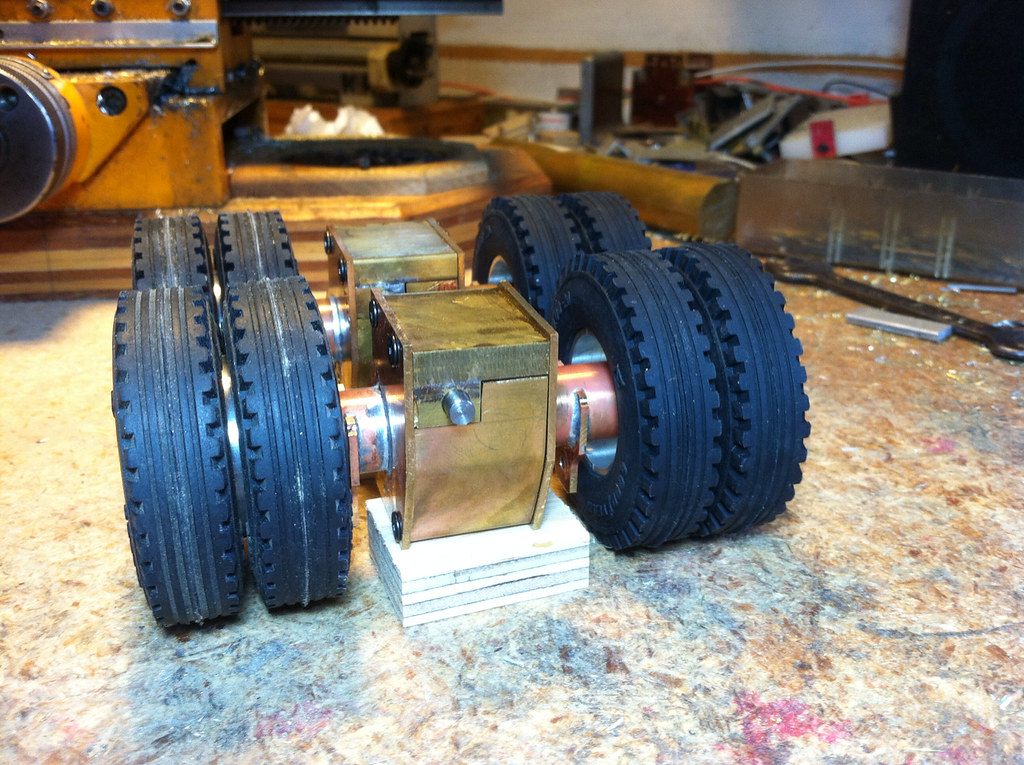

I am steadily working on the rear axles of the Faun carrier. When I last posted I had everything figured out, so now it is a matter of realizing it all and it is coming together nicely. I am pretty happy with the result. The axles are functional and hardly to scale, but they won’t be visible at all once they are in place. I put all the parts together in a mock-up to see how it will look.    Sorry Eef, but I am going to make the carrier with the lower cab. I like that one better. Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

I made the drive shaft between the axles. This was very tricky, because there is little space.  Axles FAUN Axles FAUN by kerstdejong, on Flickr Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

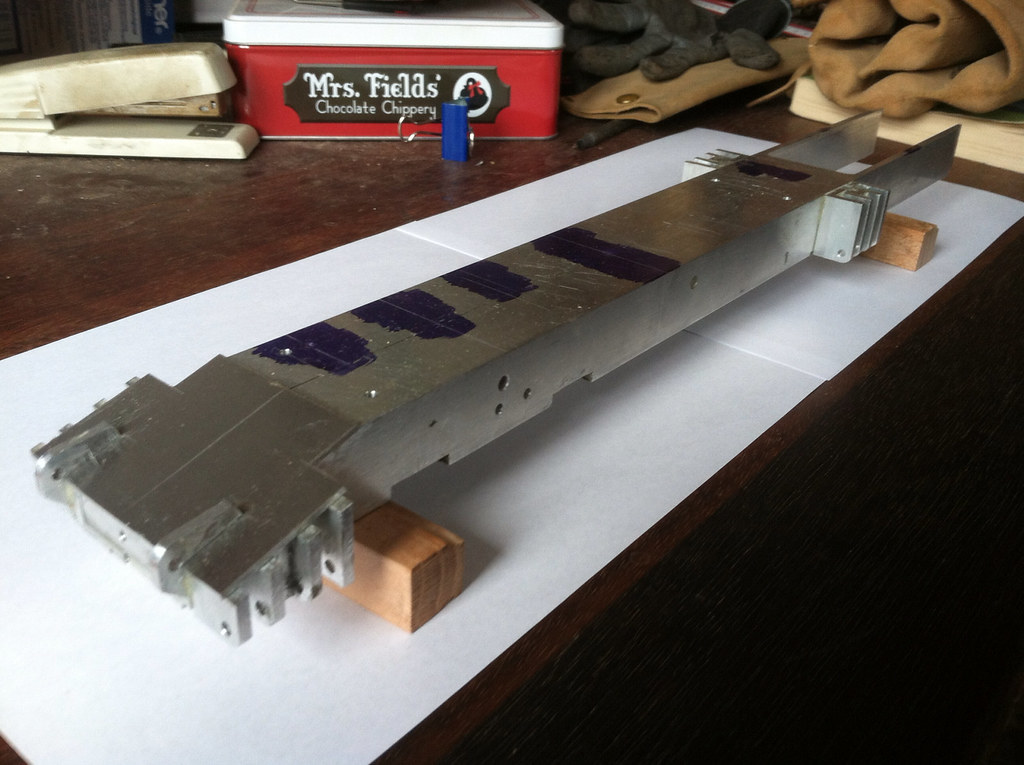

I made some progress with the wheels. The tandem axles are done and I have been working on the other wheels. These are the three axles with single tires and one of the three axles is driven. For these I used brass, because it is so easy to solder and machine. I will focus on the driven axle next. It is very similar to the rear axles. The picture shows all the front wheel parts in various stages of assembly. The bearings are 14 x 8 x 4. I got a whole lot of them for very little money:  The tandem axles with walking beam suspension:  Here is the frame, made of AL:  Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2013

Posts: 937

Location: Quebec, Canada,

|

Awesome project. Keep posting. I wish I could do such kind of stuff (precision machining) too...  I owe much respect to talented machinists who can achieve that quality work. I know one guy who builts 1 1/2 locomotives at our train club too, with that kind of dedication. That is not common, though. You guys are dreams builders.  Great work anyways! S.

___________________________________________________ Playing with toys since 1970, now building them.

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/16/2009

Posts: 903

Location: Peace Dale, R.I.

|

Truly inspiring work. Long hours, great satisfaction in the end. TM

__________________________________________________________________

Tom

It's pretty sad when the only modeling tool you own is a box cutter.

If the only tool you have is a hammer, you start to see every problem as a nail. Abraham Maslow

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/18/2008

Posts: 515

Location: Richfield, Oh (Cleveland)

|

Really nice looking work Kerst. This is going to be another grat thread from you. Can't wait to see more.

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

I made some nice progress, although things are not as finished as they seem. Today I made good progress on the third axle. I still have to finish the suspension and the steering.  kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

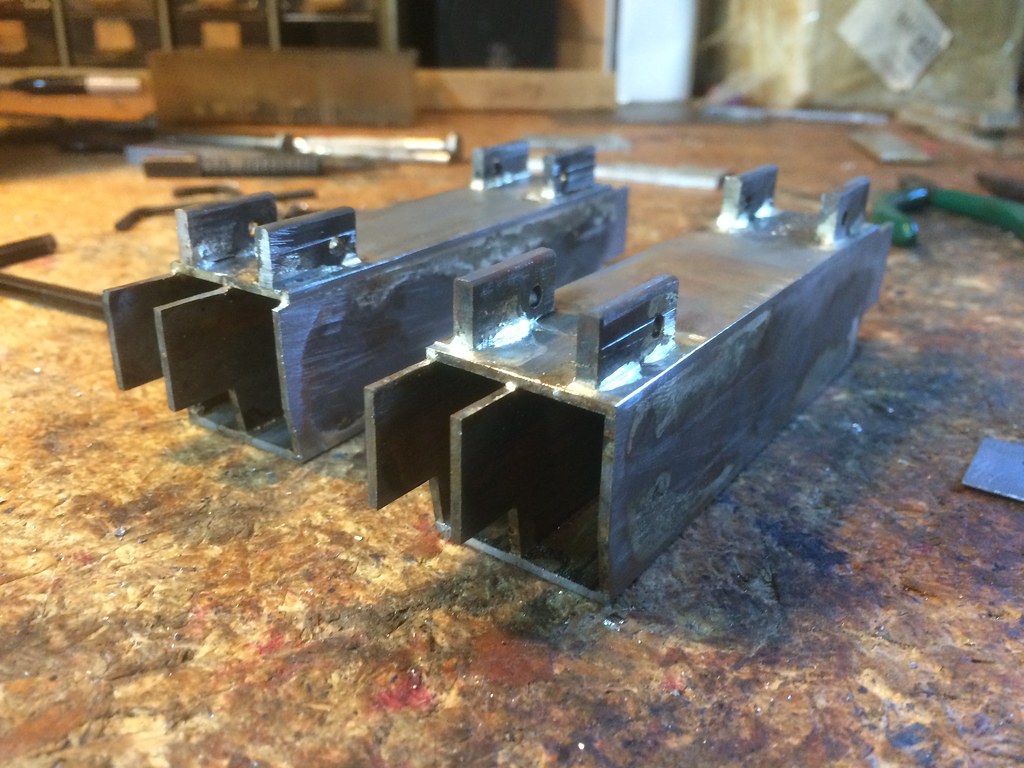

The beginnings of the cab are here:  I also started on the outrigger boxes. They are pretty straightforward. I decided on Steel and I brazed them together. Now they are definitely strong enough. The second picture shows some parts added using solder. They need to be cleaned up a bit and they are ready. Next are the outrigger beams.   Kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/8/2008

Posts: 4,174

Location: Anchorage, AK

|

American Toy Company appears to be a good source for over-size tires and other truck related items. I was snooping around the local RC hobby shop for some large truck tires and didn't really have much luck. Did you turn / manufacture the rims yourself?

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/7/2005

Posts: 1,155

Location: Copake, NY

|

ulf wrote:American Toy Company appears to be a good source for over-size tires and other truck related items. I was snooping around the local RC hobby shop for some large truck tires and didn't really have much luck. Did you turn / manufacture the rims yourself? Their tires are great. They just a little bit on the big size for this scale, so it all gets tight, but they look nice. I made the rims myself. kerst

http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251 http://forums.dhsdiecast.com/default.aspx?g=posts&m=1096251

|

|

Rank: Advanced Member

Groups: Member

Joined: 11/11/2006

Posts: 3,421

Location: UK

|

Great work Kerst. Love watching your projects.

Heavy Cranes

|

|

|

Guest |