|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2007

Posts: 1,489

Location: St. Louis, Missouri, USA

|

ulf wrote:Superb work all around. The basic 1750 is still one of the best-looking crane models out there  Especially the ones with proper track pads.

|

|

Rank: Advanced Member

Groups: Member

Joined: 8/19/2013

Posts: 764

|

Great model-making skills there. I'm not really a crane man, but I can see this would look very good in my collection

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/20/2009

Posts: 497

Location: Tulsa OK

|

JohnGalt wrote:ulf wrote:Superb work all around. The basic 1750 is still one of the best-looking crane models out there  Especially the ones with proper track pads. I don't think I've seen a 1750 post go by without you mentioning the track pads   I agree though. The first thing I noticed on the model was the track pads. It really does look excellent.

-John

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/11/2009

Posts: 570

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/20/2009

Posts: 497

Location: Tulsa OK

|

Wow, that spreader set up looks great!

-John

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/8/2008

Posts: 4,174

Location: Anchorage, AK

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/27/2007

Posts: 1,489

Location: St. Louis, Missouri, USA

|

I guess that answers my question about whether I was complaining too much about that. I'll stop now.

The LR1750 is a great-looking crane, and this customization is one of the best.

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/20/2009

Posts: 497

Location: Tulsa OK

|

JohnGalt wrote:I guess that answers my question about whether I was complaining too much about that. I'll stop now.

The LR1750 is a great-looking crane, and this customization is one of the best. I'm just messing with you. I understand where you're coming from. when this model came out, there really weren't any large crawlers and to miss something so crucial was a mistake. I agree, In my opinion, if those track pads were on the Riga Baumann model, I would have at least 2

-John

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/11/2009

Posts: 570

|

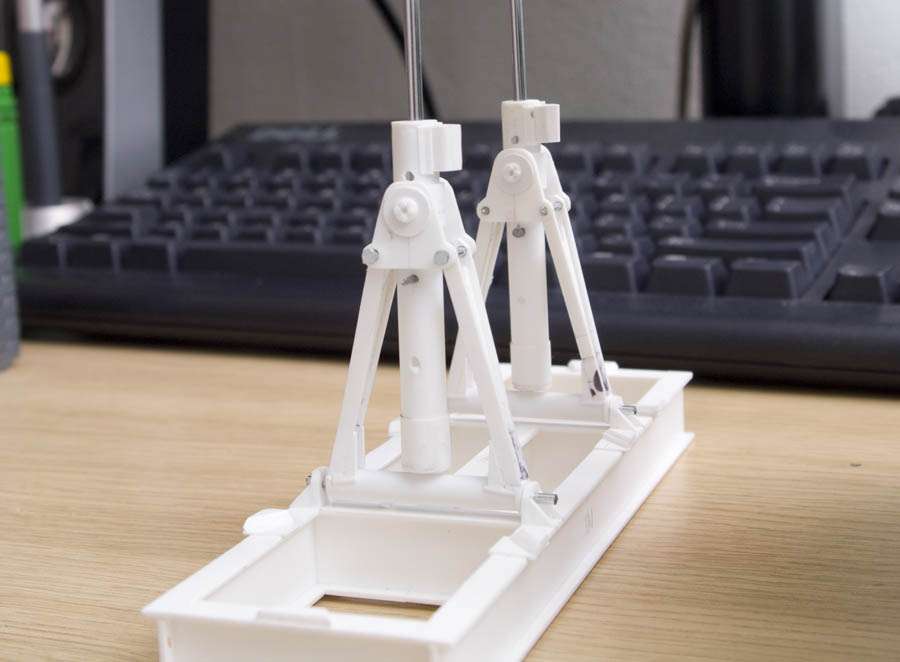

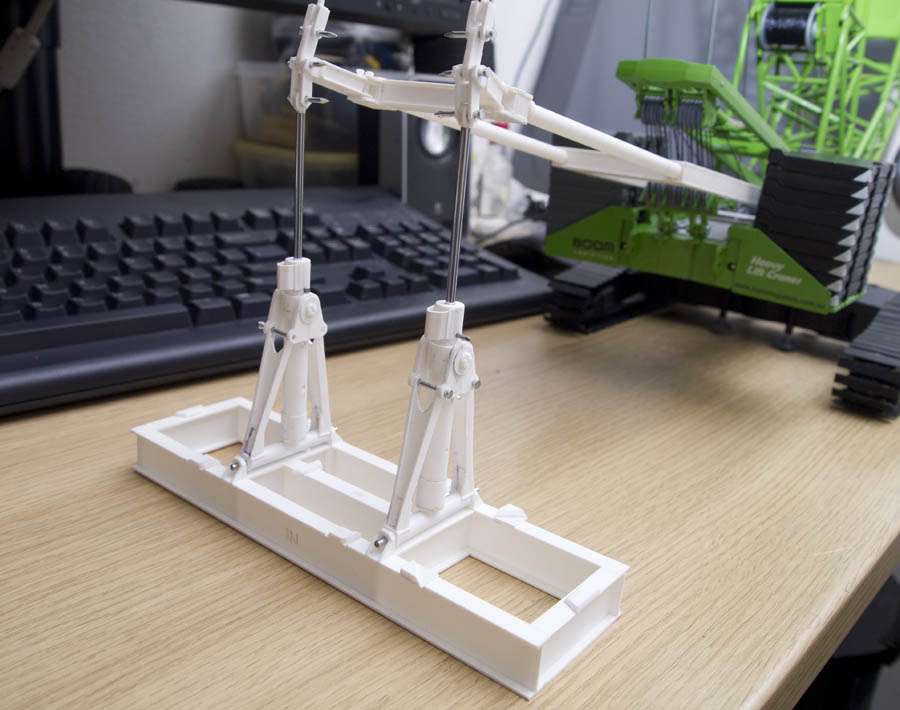

Started adding some small modifications. Found a photo of this so decided to build it - it took several hours but was an interesting process. Should get it painted tomorrow.

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/11/2009

Posts: 570

|

So I thought I'd start the ballast tray on Monday... and I did. I reckon I've put in somewhere around 40 hours work so far and there's still a long way to go in terms of finishing and detailing, but the structure is more or less finished. I'm expecting a delivery of 2.4mm tube tomorrow which will allow me to finish the cylinders (add internal resistance) and then I can do a load test. I have no doubt that this will suspend 30 of the weight slabs easily, but it's possible that the cylinders will creep, but I wanted as much realism as possible and that means having cylinders that are functional. This has been without a doubt the most challenging project I've ever undertaken, and it's driven me almost to the point of insanity - I have no patience left and I'm taking a break!

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/11/2007

Posts: 9,080

Location: Lincolnshire

|

Looking really good Davie!

Paul R

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/22/2007

Posts: 5,860

Location: Louisville

|

Nice job Have you considered using ycc cylinders? Not sure which ones would be closest to the size but they are worth the price? Wish he made cylinders for every truck crane, a lot of them need them

Brandon my youtube channelMy Facebook Page

|

|

Rank: Member

Groups: Member

Joined: 6/30/2014

Posts: 77

|

Dont forget to add the beacon at the top for low flying aircraft. Hahaa. What an amazing job with the styrene. Ive done alot of styrene work with 1/16 scale tanks and know whats involved. What glue are you using?

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/8/2008

Posts: 4,174

Location: Anchorage, AK

|

Super work on the ballast tray - an excellent addition to the 1750. I had thought of purchasing an "aftermarket" version a few years ago - a few very skilled craftsmen out there build brass duplicates - and also looked at scratchbuilding a styrene version. I have several fairly well detailed photos if you need them, but you appear to have a good handle on the project. I was a bit concerned that styrene may not be adequate for the load - especially if using the original diecast weights...

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/11/2009

Posts: 570

|

Thanks for the comments guys. Brandon, yep I thought about brass cylinders but my main gripe is that they just don't look as good, especially with the grub screw in the top. I've been using chrome plated aluminum tube for my cylinders and it looks very realistic; I wouldn't use anything else. mcm308, thanks. Back when I started building with styrene I was using Humbrol Liquid Poly, however for a short time I was using Revell Contacta. It's more viscous than the Humbrol and easier to work with but takes longer to set and is considerably more expensive. Just recently I went back to Humbrol Liquid Poly and I wondered why I ever stopped. Ulf, thank you too. I also thought about getting a ballast tray when I last had the LR1750 however I'm really glad I didn't - even the aftermarket ones are not as faithful to the original as I'd like, which is why I thought about making my own. As for styrene handling the load, it is remarkably strong provided it is welded together adequately. Here's the tray I made for the CC8800 not that long ago, fully loaded with 52 terex plates and suspended by four very small strips of 1mm styrene and a couple of 1.25mm steel tacks. It sat like this for several days with no ill effects.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/4/2006

Posts: 7,752

Location: arlington, Tx

|

Great work I am liking what you have done. Will be a great looking model when you are done. Jason

NIkl Scale Models

|

|

Rank: Advanced Member

Groups: Member

Joined: 11/13/2012

Posts: 1,001

Location: South oz THE ASS END OF THE MURRAY RIVER , Austral

|

As everyone said awsome work. wished i had that sort of scratch building talent & painting skills. i'd love my 1600/2 in that aussie livery .

Sent from my HTC M10 - Rooted , using S-OFF , Open Home 6 & Buuf icon packs http://forum.xda-developers.com/ BUILD YOUR OWN PHONE

|

|

Rank: Advanced Member

Groups: Member

Joined: 5/11/2009

Posts: 570

|

Thanks guys. So my styrene tube arrived in the post this morning which meant I could try a load test on the floating tray. Suffice to say it didn't go as planned, with one cylinder creeping if I added only 6 plates to the tray. So onto plan B which was to pin the cylinders at three points: short, medium, fully extended. This was pain to do because there is a piece of styrene rod running inside the aluminium tube, so my drilling had to be very accurate. The plus side is that it is very VERY strong when pinned in place. I also added the mouldings for the counterweight blocks so that they are secure when loaded.  Here's the tray fully extended and the cylinders also fully extended:  Something I didn't mention before is the two pendant lines I had to make myself because I required a custom length. All the weight will be supported by these two parts of 1mm styrene, which is the same idea I used on the CC8800 tray.  And onto the lift test - I used a 2kg (4.4lb) weight plate at a large radius to get the tray off the ground, and called it a day when I reached 3 stacks of 9 because I'm just never going to need that much weight on it. I even had to empty the superstructure ballast.

|

|

Rank: Advanced Member

Groups: Member

Joined: 2/14/2014

Posts: 151

Location: Dallas

|

THAT LOOKS AMAZING

Fully loaded that looks awesome and your whole project is awesome

|

|

Rank: Advanced Member

Groups: Member

Joined: 1/11/2007

Posts: 9,080

Location: Lincolnshire

|

This is an incredible project and I've enjoyed the ride so far. Can't wait to see it all completed.

Paul R

|

|

|

Guest |