|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

|

|

Rank: Advanced Member

Groups: Member

Joined: 10/23/2006

Posts: 211

Location: cleveland

|

I really like the color scheme of Interbeton. Does't someone make a model of the truck hauling the Interbenton excavator, I thought I saw one.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

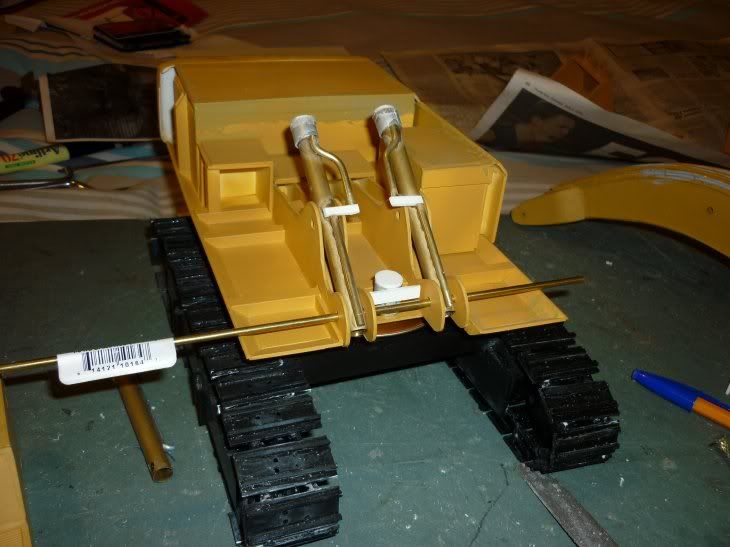

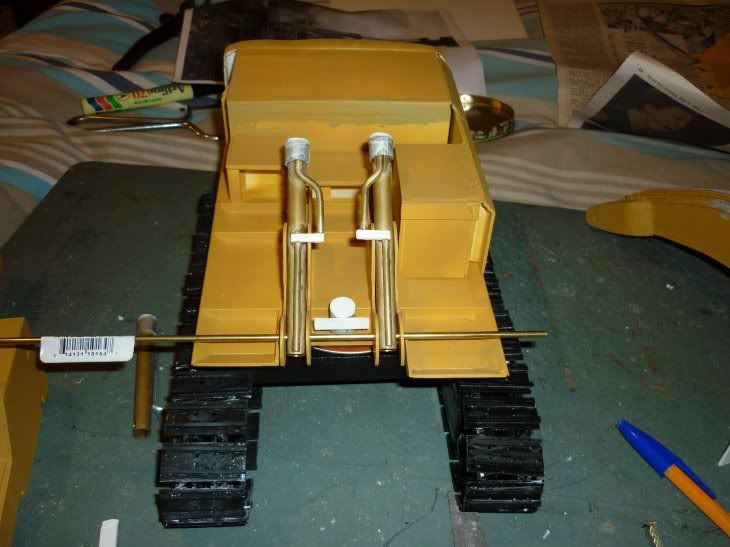

Hi all, time for a small update. You wouldn't believe it but back in January, I finished my second set of track pads and they were ready to be attached to the undercarriage. Between then and now, they went missing and after tearing my room apart and throwing everything upside down, I'm pretty sure they have been mistakenly thrown out  Anyhow, after a lot of cursing and a few beers, I decided it was time to get going on the ummmm 3rd set now! Anyway, 2 days later, I managed to get the set cut, glued, painted and attached. Finally! I also spent some time this afternoon working on some of the other small details. I built the swing ring motor, added some lines to the hydraulic cylinders, engine cover details and primed some more parts. Unfortunately I think that today was the last sunny day for quite some time now so final paint will once again be delayed. I have a lot of work to do before then anyway. It's all the smaller detailed parts now that take up so much more time. Well 2.5 years into the build, here is how she stands at the moment. Sorry for the poor quality images, they were from my phone, left the camera at work. It's far from perfect but I'm very happy with it so far.      Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/8/2005

Posts: 348

Location: Western Australia

|

Great job Rowan, I am not clever enough to do that sort of thing, but I do enjoy watching things and see how they progress,, I'm sure your's will look like a Don Campbell model by the time its finished,,

Regards from the west

Peter

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Hi Peter, thanks for the kind words. I'm glad you've enjoyed following the build. My model is far, far, far from a Don Campbell creation but I do appreciate the comparison  I can't wait to get her finished, I have a heap of other project on my plate as well. Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/30/2008

Posts: 3,439

Location: Good ol' Indiana

|

Your excavator looks to be coming together well. The undercarrige is nice.

-Ethan Collection 8/2/2016For more of the Diorama and my collection: On Facebook or On YouTube

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/1/2006

Posts: 4,065

Location: Dublin Ireland

|

good stuff Rowan,she's gonna be a beaut!!! you'll have to get cracking on a KW and Drake set up now too

Why is "phonetically" spelt with a "ph"? ... It's better to be silent and thought a fool, then to speak up and remove all doubt The complex of Newgrange was originally built between c. 3100 and 2900 BC,[2] meaning that it's aproximately 5,000 years old. According to Carbon-14 dates,[3] it is more than 500 years older than the Great Pyramid of Giza in Egypt, and predates Stonehenge by about 1,000 years.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Basketball Man wrote:Your excavator looks to be coming together well. The undercarrige is nice. Thanks mate, I'm happy with the way it's coming together. Big gaps around the drive motors but I think it's close enough to look semi decent. gbarnewall wrote:good stuff Rowan,she's gonna be a beaut!!! you'll have to get cracking on a KW and Drake set up now too  I've always thought about a Euoropean setup for a haul but a Drake float seems common sense. I have a Kenworth W900L that will pull the load... Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

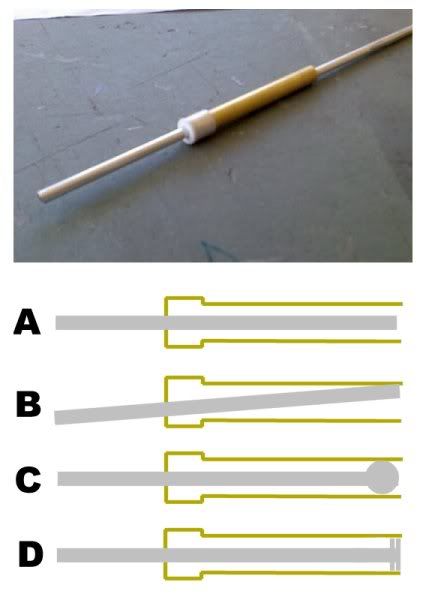

Hi all, I'm on holidays this week and have been doing a little bit of work on the CAT, hand rails, hydraulic lines, walkways etc, just the small stuff the weather is cold and windy at the moment so no painting. Anyway, I was looking for some advice. I'm currently looking at cutting the hydraulic cylinders and stopping them off. Here's where I'm at... A: As it is at the moment resting B: The current play / movement it has available C: My favored option (using a small metal ball) D: My secondary option (using metal washers) To allow the ram to slide within the cylinder without giving it the opportunity to jackknife, I was thinking of either C: Adding a small ball-bearing or fishing sinker that will limit movement but allow for slide. Or D: Gluing a couple of small washers on the end of the ram (Which I believe is more realistic but probably wouldn't allow the ram to slide as well.)  Has anyone here had any experience with building cylinders to offer an opinions or perhaps some alternatives? Thanks in advance... Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 4/21/2003

Posts: 756

Location: Athens, Alabama

|

Hi Rowan.

You could take several short sections of tubing of the necessary diameters and glue together to get the needed outside diameter that would fit the inside diameter of the cylinder. Whew, that's a mouthful.

It would resemble illustration D, but the "bushing" would be a little bit longer.

I guess another way of decribing what I said at first is to visualize telescoping tubing, collapsed to its shortest length, and cut off a section of that, and glue it to the rear end of the piston. A similar sized piece would be glued to the end of the cylinder on the inside. This would allow the piston to slide, but with minimal jack knifing.

Hope my idea makes sense, because I am not sure that I could explain it any better.

Good luck on any of the methods that you may use.

Regards, Colin

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Colin, I understand exactly what you mean. Thanks for the the idea, I'll give it a go for sure. I think I'm going to buy some bits and pieces and just see what works best. Thanks again. Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 12/25/2006

Posts: 4,275

Location: Woodland, WA

|

Another option would resemble "D" but instead of a metal washer, make a groove in the end of the rod and install a very small rubber O-ring

Eric W. Pioszak, Operating Engineers Local 701, Portland, Oregon

METAL TRACKS AVAILABLE AGAIN!

Cab guards Available again!

Grapples Available again!

Industrialscalemodels[at symbol]Gmail.com

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/9/2010

Posts: 218

Location: Vila Velha - Brazil

|

Eric Pioszak wrote:Another option would resemble "D" but instead of a metal washer, make a groove in the end of the rod and install a very small rubber O-ring I agree with Eric. You can make the cylinder as the real, working on 1:25 scale it's very easy to find the materials.

Andrea Life is for crazy people  Models For SaleFB Models For SaleFB

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/23/2010

Posts: 701

Location: Washington, DC

|

I missed the hauling thread in this, but here in the mid Atlantic region consider yourself lucky if you only have to pull counterweight, bucket and stick.

Some years ago was involved in moving a Hitachi EX550 mass excavator for Virginia to Maryland. The bucket, stick, boom and counterweight were pulled. The machine on a Talbert tri-axle beam with a short hood four axle Peterbilt 379 required Virginia superload permits, i.e. over 110 thousand. Permits were for 113,500 gross. The scale weights were just under that and yes a ticket was given on axle distribution. It was not significant so they allowed the fine to be paid and the load to proceed. This is one reason the Hitachi was sold after two jobs to a sand and gravel mining operation. We had looked at a used 375 ME but knew that from a competitors experience that he was required to pull the tracks in addition to what we had done. I remember that it took something like seven loads to move it.

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Thanks for the input again guys. Eric and Andrea, I'm sure I can dig up some O rings from the garage, I'll have a look around tomorrow afternoon. The idea never even occurred to me and will probably work best. I bought a bag of small fishing sinkers this afternoon and have toyed with Colin's idea of a built up rear sector of the ram as well. I'll post some pictures after I've experimented some more. DC Craneman. Sounds like you guys in the Mid Atlantic region have your hands full moving the bigger stuff around. I would prefer the trailer I build to be as simple as possible as I have little to no knowledge about them. That being said though, I would like it to be fairly accurate. An Aussie Float would be ideal but I think they are beyond complicated for me. A European setup like this (Nooteboom?) trailer below would be perfect however I just don't think it would look right being pulled by a Kenworth W900L.  I think that I'm going to settle on this Rogers 100-ton SP100-4XDRR4, Specialized, Detachable Rear Trailer. I believe that a 375 is closer to 80ton when fully setup and I could probably build this trailer without too many problems. It would also look good behind the W900L and is close to realistic. http://www.rogerstrailers.com/116-000/trailer_details.php  My next question, would a Kenworth W900L be able to haul a trailer/excavator combo like this without too much issue? Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/23/2010

Posts: 701

Location: Washington, DC

|

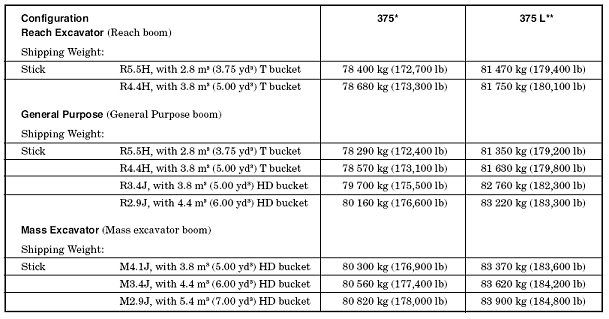

I'd have to check my Cat handbook on the total operating weight of the 375, but a 245 was right around 75 tons all together. Hence a 75 to 85 ton trailer would not be unreasonable. Nice match with a Rogers of this size range.

Yes a W900L correctly set up would do the job. A major earthmover here has one as their newest tractor. Also look at Catom in the Chicago area. They do not seem to be as popular in the west as the cooling options are the most restrictive on the W900L and T800B in the KW line and relative to some competitors. Cooling and shorter wheelbase make the T800W the other ideal KW lowboy tractor. Make sure the detail is of adequate mass to represent at least an 18,000 pound front, a lift axle (13,000 to 23,000 pounds) and 46,000 two speeds for a nice reasonable set up. Based upon scale, don't forget the double frame and heavy fifth wheel details as well. Based upon your tractor detail, Cat C15 or Cummins ISX are the other recent choices. Some extreem heavy haulers will add a two speed auxiliary to this but that is more than would be needed for a lowboy.

Other commonly seen trailers in this application would a Talbert or Trail King. Many manufacturers stop at 50 to 55 tons capacity. If modeling a western truck, I would go the T800W or a Pete with your preference of Cozad, Murry, Peerless or Rackley of correct configuration.

While I like the image of a W900L, often in lowboy work you want to transfer as much tractor weight onto the front axle as possible so that your rears and lift axle carry as much load as possible. Hence you sometimes see longer wheelbase setback axle tractors. They are trying to keep as much engine, transmission and cat weight as possible from being transferred to the rears.

|

|

Rank: Advanced Member

Groups: Member

Joined: 9/16/2007

Posts: 2,707

Location: Staten Island, New York

|

I think the 375 was just about 83 tons (?)

-Vinny http://www.heavytruckphotos.com/

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Thanks again for all the information guys, DC Craneman thanks for the excellent write up! While I would have prefered a T800W for my configuration, I found a realistic yet cheap R/C Kenworth W900L that I've already purchased so I'll be able to R/C my haul around the yard. I went through the PDF and found the weights. I believe that I built from the plans of a 375L with the R4.4H stick making it 81,630. Perfect for a 100t Rogers.  Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 6/30/2003

Posts: 4,920

Location: Melbourne, Australia

|

Well I bought a new camera today, cheap little compact digital, but it takes better snaps than my phone (which I've been using recently). Colin, I had a continuous roll of light aluminum - about 0.5mm thickness - that I cut and wound around the ram. Unfortunately it was really hard to keep wound and the clamps ended up getting glued to the binding. I would have tried different circumference metals like you suggested originally if I had them available. It would have worked as suggested. Oh well, attempt No. 2... Searched for the O-rings in the garage, I'll take a good photo of my garage tomorrow. I'm not kidding when I say it looks like a small car workshop. It's an Australian garage. Probably 5m wide (16ft) about 20m (65ft) long and packed to the rafters with all sorts of worthless rubbish. Dare say, I couldn't find them, so I bought a small pack of the ball bearing fish sinkers at K-Mart.... My luck, I got home and went for another look, I found the tiny o-rings that I was looking for in the garage... Success!!...  They are a perfect, and I mean a perfect fit. Now the hydraulics move and feel like they should. Absolute no play and there is a slight resistance in the slide. I am very happy. My father dropped by today and he was a train builder for our country side trains. He was very impressed.  So here she sat....  I bought some new brass and did a bit of work on the boom lift hydraulics. The piping is way too think to scale but I think I can get away with it with most folk  I also finished the side walkways with some of the K&S photo etched cross hatches brass and I'll get some more pics tomorrow. The walkways look great but the mountings along the sideboards are going to take a few modifications.    Far from perfect but close enough for me. I'm most worried about gluing all the hydraulic hoses last after final paint. PS. I realise that the RHS cylinder is high, just have to make a few adjustments to settle it. Right now the list of things to do is quickly shortening. I have most of the body hand rails already cut. I just need to think of everything in a sense of assembly. Everything I glue has a 2 inch white ghost (fume) effect on it and I don;t want to do too many touch ups. Anyway, enjoy... Rowan.

1:25th scale CAT 375L excavator

|

|

Rank: Advanced Member

Groups: Member

Joined: 3/14/2005

Posts: 427

Location: Co. Sligo, Ireland (Galway)

|

RowanH wrote:I'm most worried about gluing all the hydraulic hoses last after final paint. If you use flexible black rubber tubing for the hydraulic lines and leave a short 3-4mm long pin sticking out from the cylinder where the hose connects, then slide the tube over the pin and it will hold. That way you can take it off when needed. My sister got some of the tubing in a bead shop but I "acquired" it off her later! Still havnt decided what to use it for yet  dont want to waste it!

Engineering; Its all STRESS and not just Force over Area!

|

|

|

Guest |